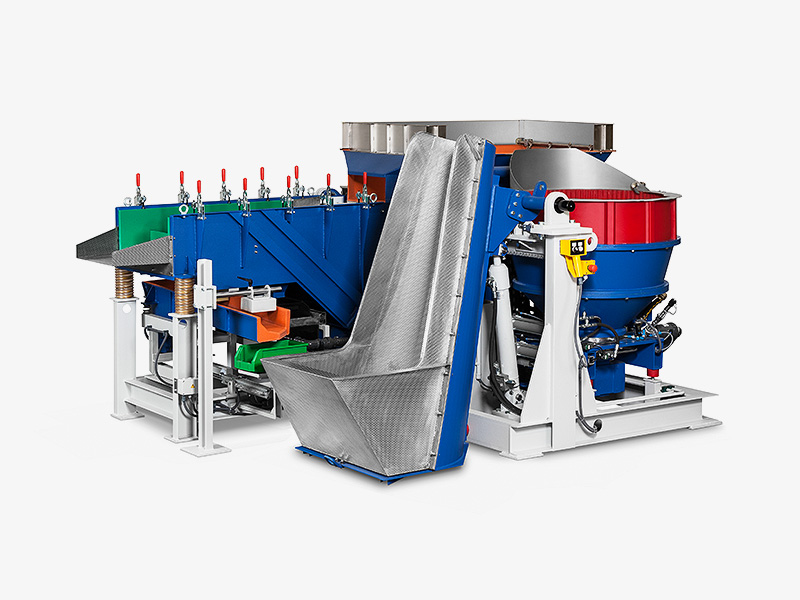

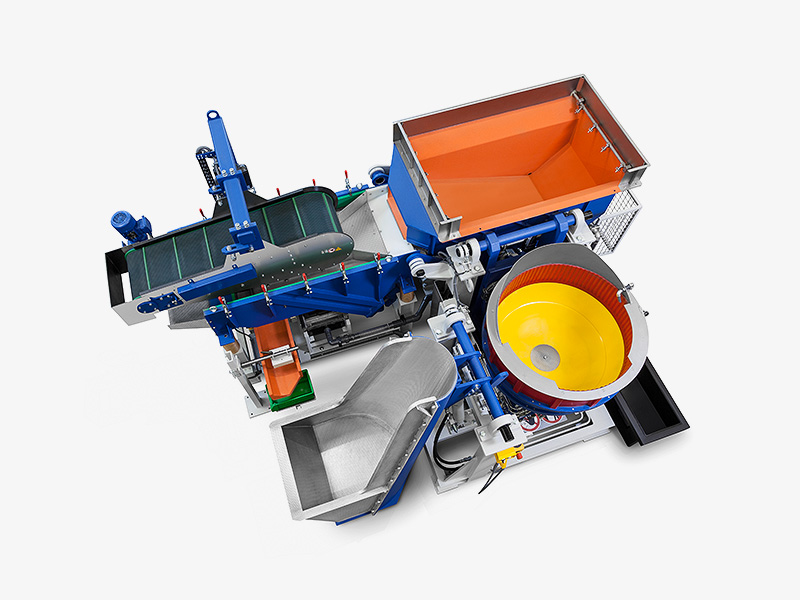

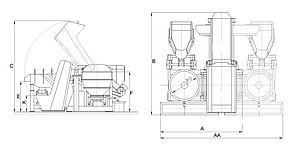

TT...A/2C centrifugal disc finishing unit

Two-batch principle for cost-effective mass finishing

With a centrifugal disc finishing unit from our TT...A/2C range, you can process your workpieces quickly and increase productivity. The machine allows you to fill a second batch into the centrifugal force tank whilst the first batch is being separated on the screening machine. This helps you minimise costly auxiliary process times. It is also perfect for automating your processes.

Save space and costs with tandem units

We recommend using a tandem unit for mass finishing processes with longer processing times and short separation times. This centrifugal disc finishing unit has two work bowls but only one intermediate buffer and one screening machine. The two work bowls are alternately emptied into the screening machine, helping to save time, space and costs.

The benefits at a glance

- High productivity thanks to two-batch principle

- Minimised auxiliary process times

- Perfect for automated processes

- Save time, space and cost