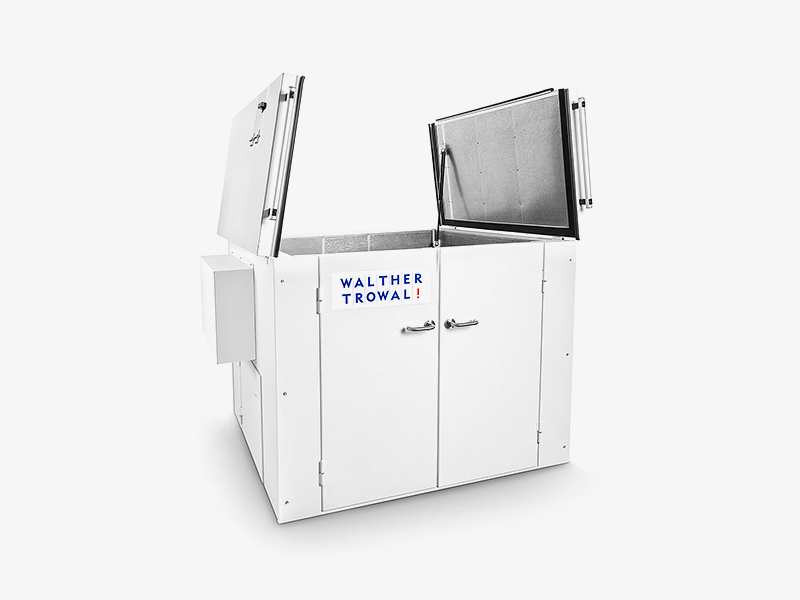

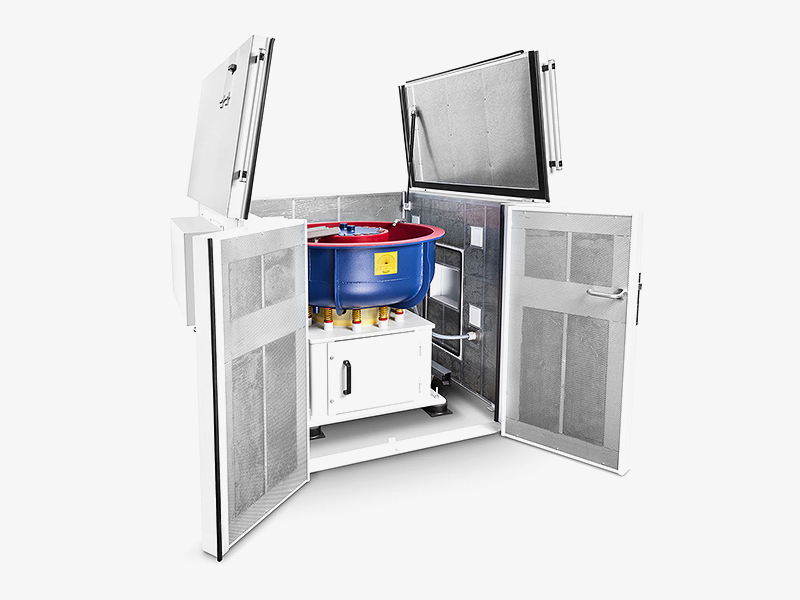

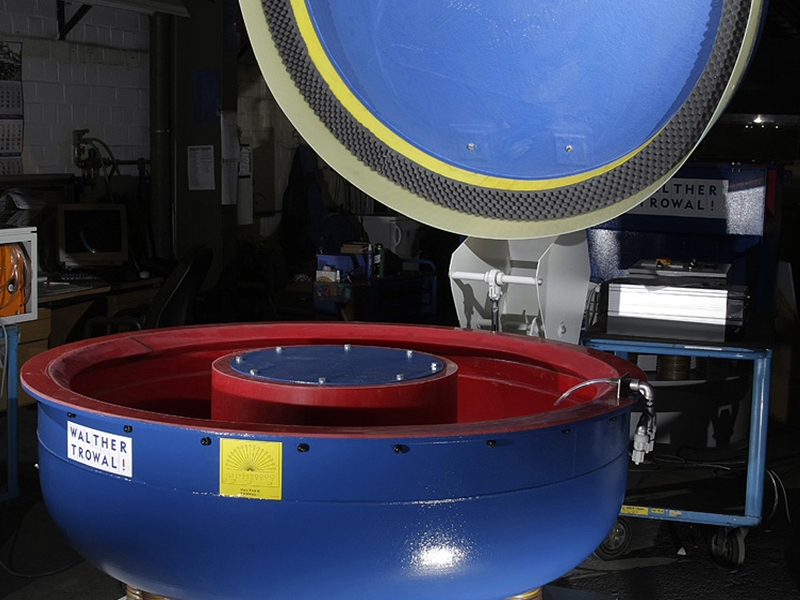

CM circular vibrators

The specialist among the all-rounders

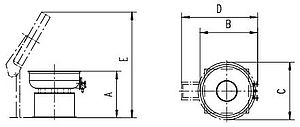

The CM series is best for processing large, heavy and sensitive workpieces. They are available in seven configurations with bowl volumes ranging from 115 to 1,000 litres. You can also choose from a wide range of accessories – such as for sound deadening or metering – to ensure that the CM circular vibrator fits your requirements precisely.

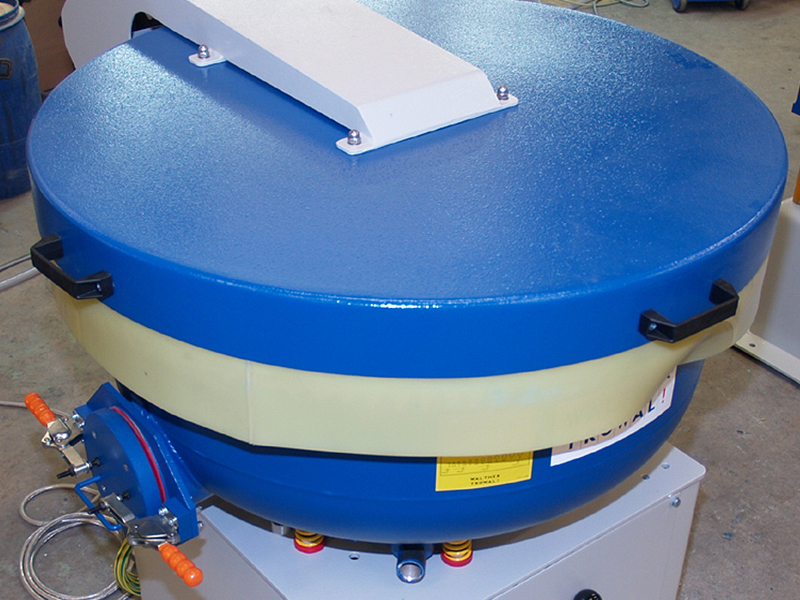

Processing sensitive workpieces

To ensure that your sensitive workpieces are processed gently, we have purposely not fitted the CM series with a screening unit. Depending on your individual processing goal, you can choose a moving separating plate and pneumatic bowl outlet. These both help keep sensitive components apart so they do not damage each other.

The benefits at a glance

- No screening unit

- 115 to 1,000 litres gross volume

- Flat bowl bottom

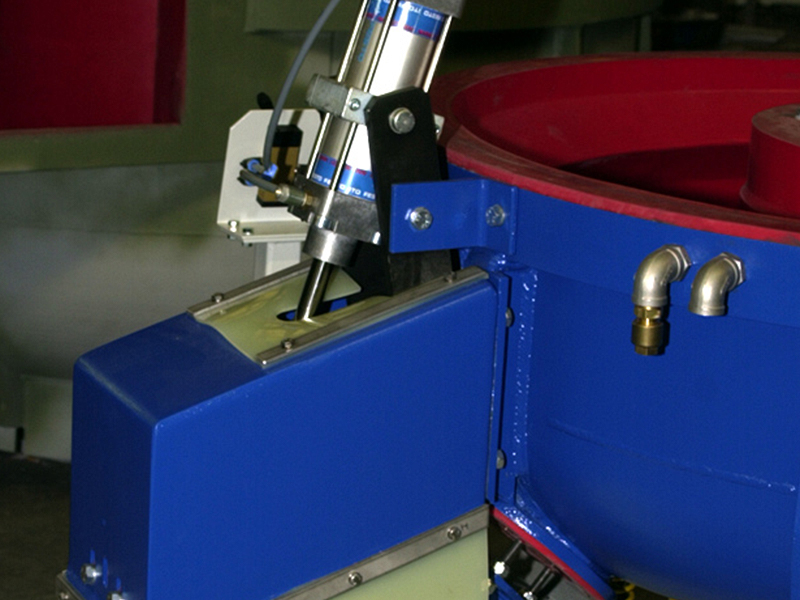

- Pneumatic bowl outlet (optional)

- Moving separating plate (optional)

- Two-batch operation possible, with minimal auxiliary process times

- Wide range of accessories available