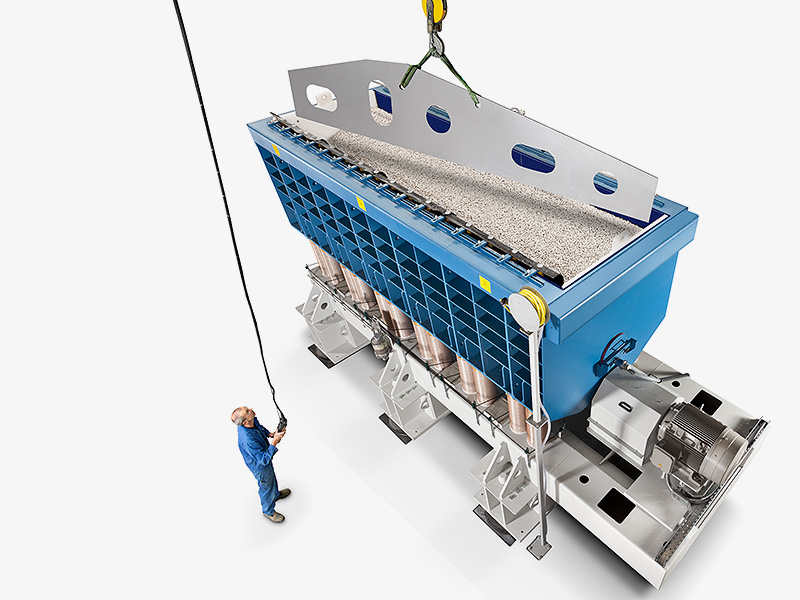

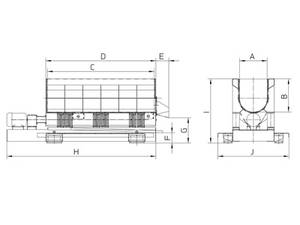

TMV vibrators

Powerful and efficient

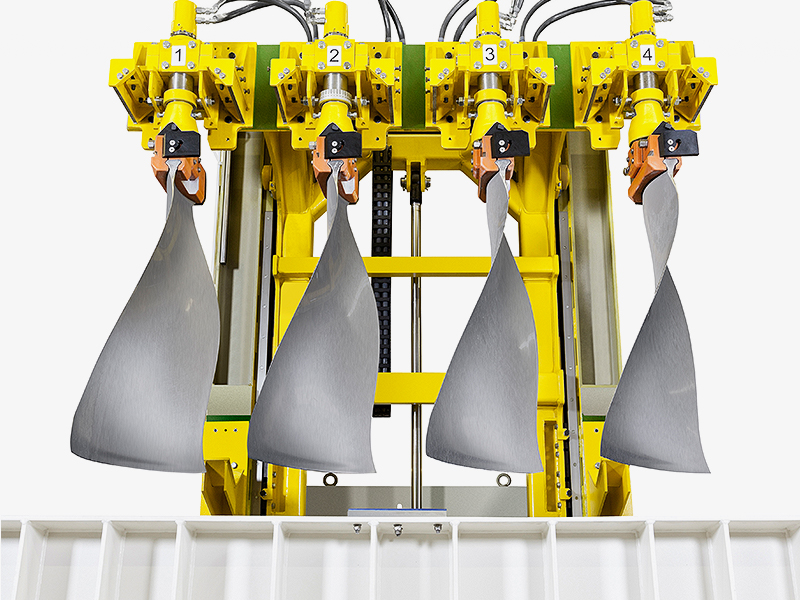

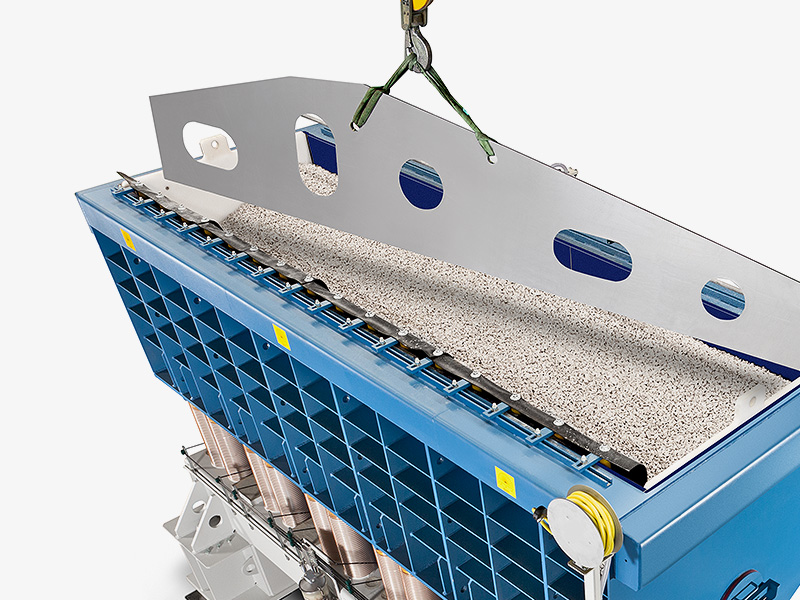

Thanks to their "Multivib" drive, the TMV range of trough vibrators ensures intensive workpiece processing throughout the entire bowl length. The extremely powerful drive also makes the machines suitable for ball burnishing and pressure deburring.

Various bowl sizes

The modular series of the TMV range allows you to select the right bowl size for your requirements. This helps you save both costs and energy when processing your workpieces.

- Bowl widths: 410, 550, 650 and 850 mm

- Bowl lengths: 1,750, 2,600, 3,450, 4,300, 5,150, 6,000 and 6,850 mm

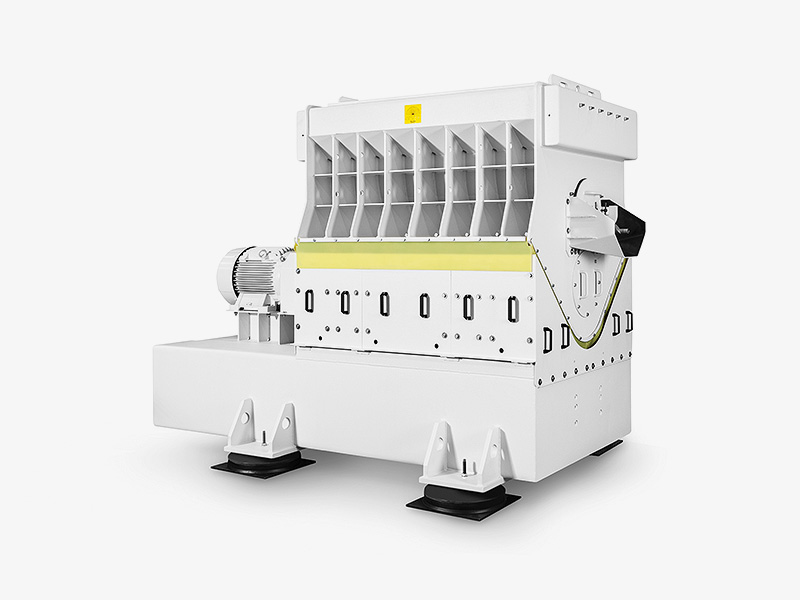

Sound deadening ensures low noise levels

Noise levels can be high, especially in a hall. That is why the TMV trough vibrators are fitted with a sound deadening lid, with complete sound deadening housings also available. Larger systems also feature walk-in sound deadening cabins.

The benefits at a glance

- Powerful "Multivib" drive

- Modular series with various bowl sizes

- Fitted with sound deadening equipment

- Ideal for ball burnishing and pressure deburring