Foundry industry

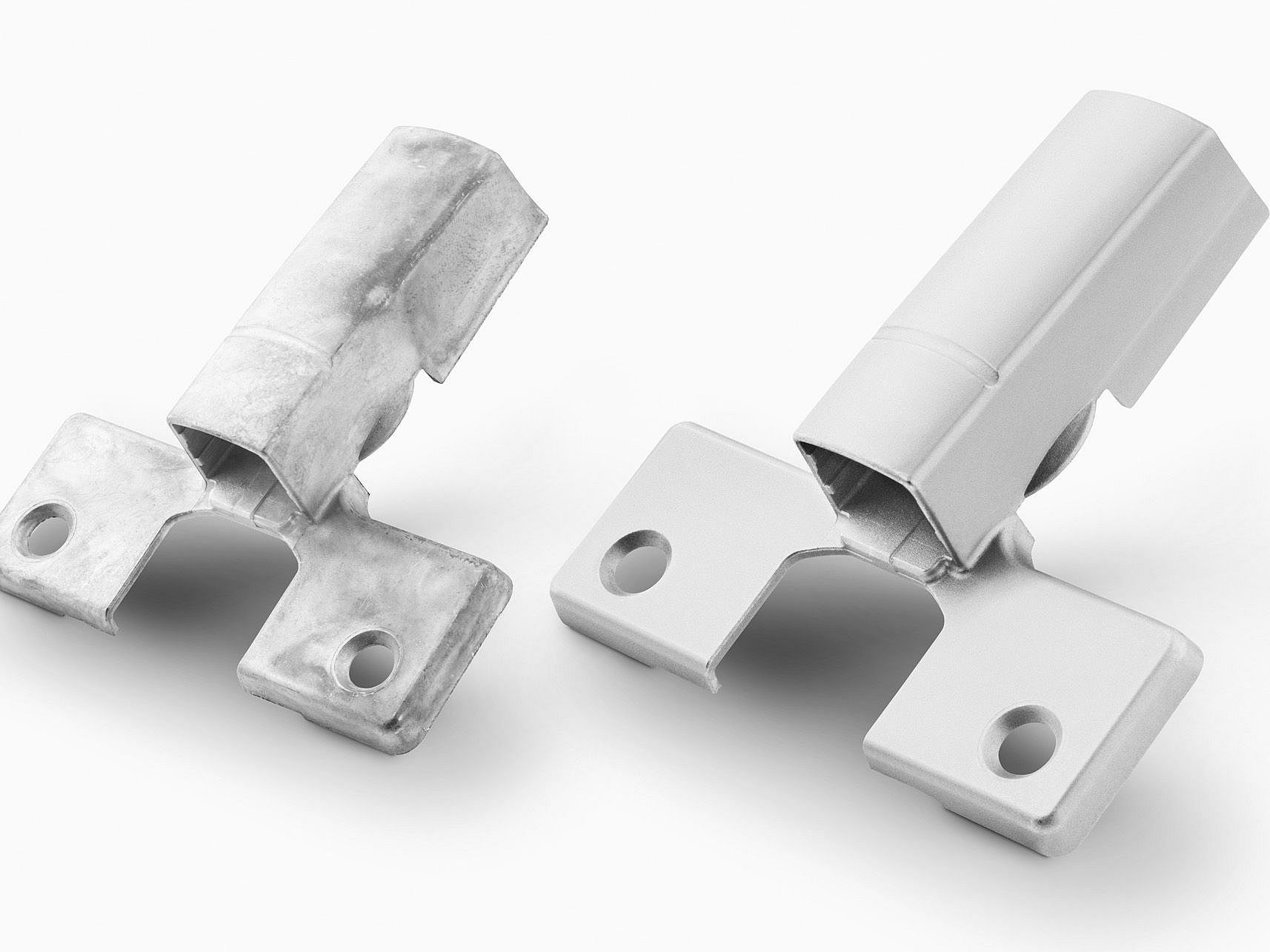

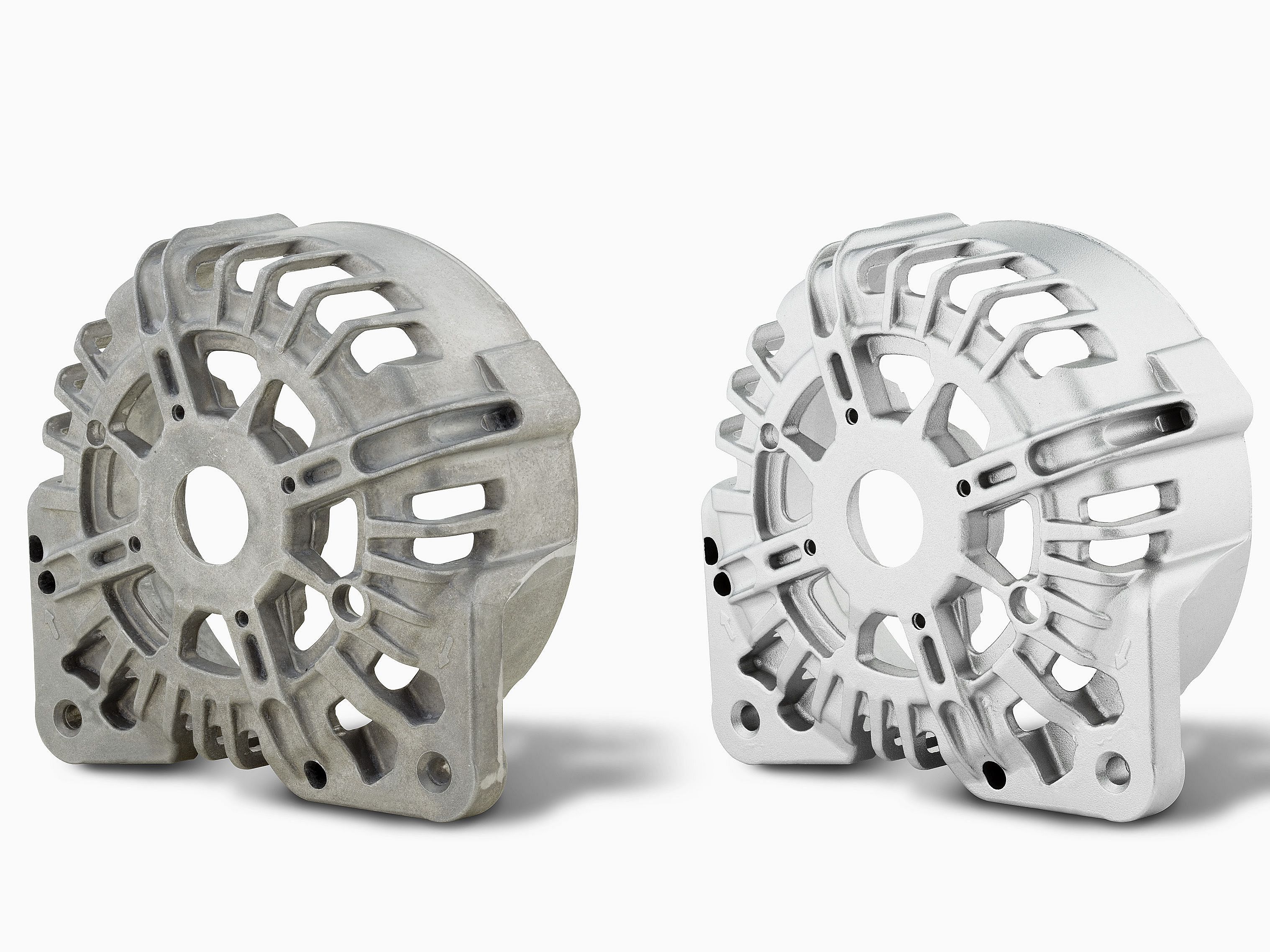

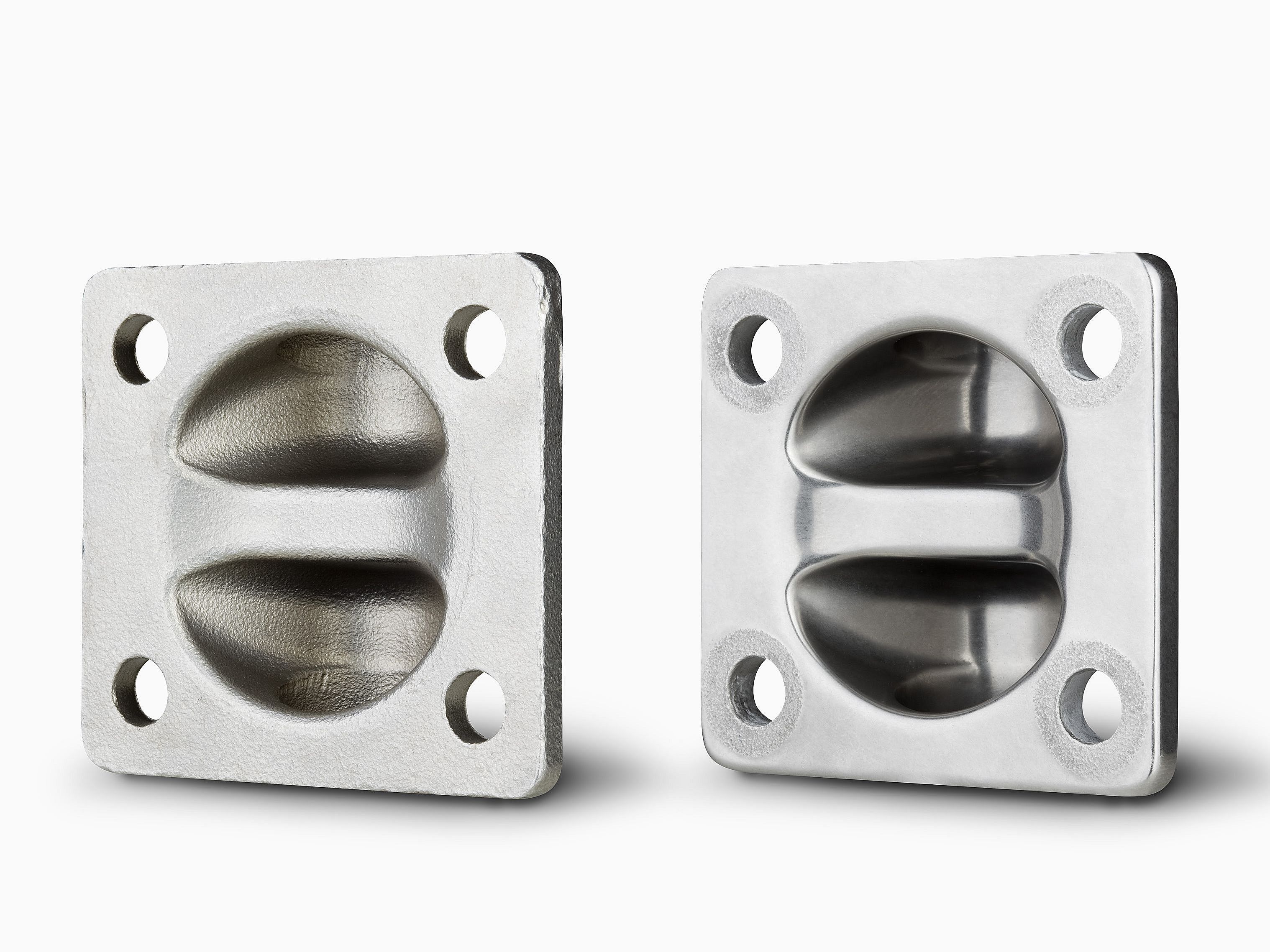

The surface requirements for work pieces created by gravity- and die-casting vary from product to product: Some must only be deburred, whereas others require a specially defined surface roughness. But there are also products, where a homogeneous color scheme or the precise radiusing of edges is most important.

For this product variety Walther Trowal supplies a broad range of mass finishing and shot blast equipment, working in either batch or continuous flow operation.

Multiple technical aspects must be considered to select the right machine for a certain job: For example, the work piece shape and weight, the production volume and the optimal integration of the equipment into the customer’s manufacturing process. Our specialists will gladly assist the customers in organizing their manufacturing processes in an effective and cost-efficient manner.

Shot blast machines

The troughed-belt continuous flow shot blast machines, type THM, offer a very high throughput capacity. While gently tumbling over each other, the work pieces are continuously transported through the machine and, at the same time, exposed to an intensive blast stream

In these machine die-castings are de-flashed and receive a homogeneous, mat surface finish, whereas on other castings the scale from the casting process is removed.

Mass finishing machines

Mass finishing machines are primarily used for surface smoothing, de-flashing and edge radiusing. The AV linear, continuous flow vibrators are ideal for handling high production volumes.

Continuous flow equipment like the AV linear vibrators, the THM shot blast machines or specially designed continuous flow rotary vibrators are frequently integrated into interlinked manufacturing systems. Continuous flow manufacturing processes allow the effective and gentle processing of the work pieces at the exact speed of the manufacturing line. The integrated work piece logistics guarantee a high degree of automation and lower inventory levels of work-in-process goods. Therefore, they become an essential part of the manufacturing process chain.

Sales Manager