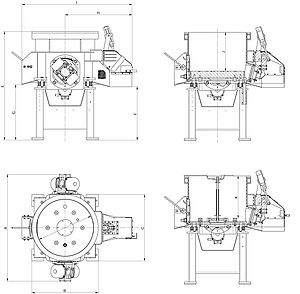

MV multivibrators

The finishing touch for complex shapes

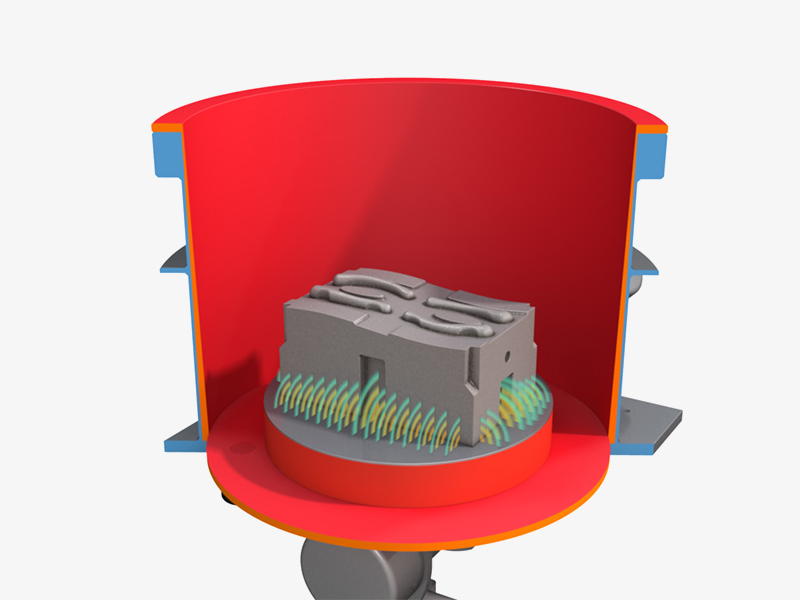

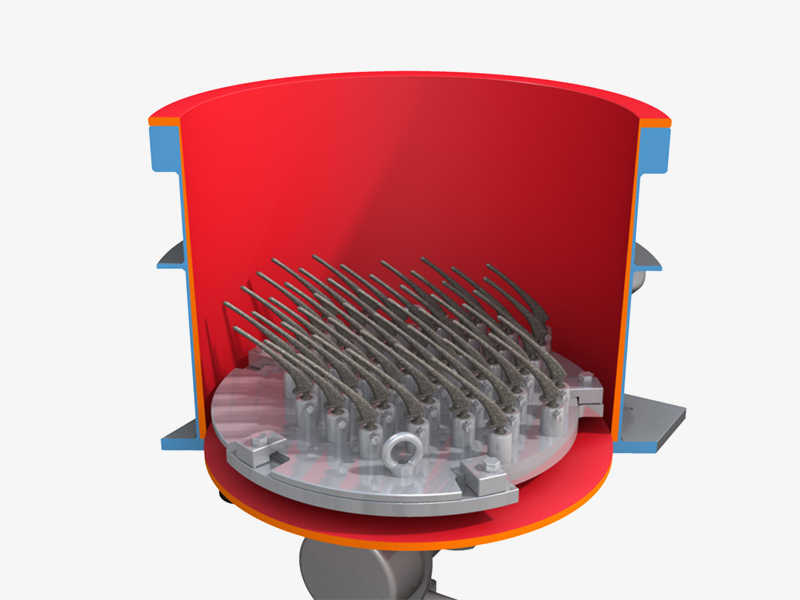

If you have workpieces with hard-to-process contours that require fine finishing or polishing, the multivibrators of the MV series are the ideal choice. The respective workpiece is secured mechanically or electromagnetically, and processed using vibrating abrasive media and special fluids. This ensures a consistent finish on both the internal and external surfaces.

Automated internal finishing on premium parts

Our multivibrators each have three high-speed imbalance drives that allow you to vary the position and rotation direction. This enables extremely small vibration amplitudes, ensuring high surface quality for your workpieces – even on difficult-to-reach areas. Delicate bars are protected, the workpiece contours are retained, and even small-diameter boreholes can be processed internally.

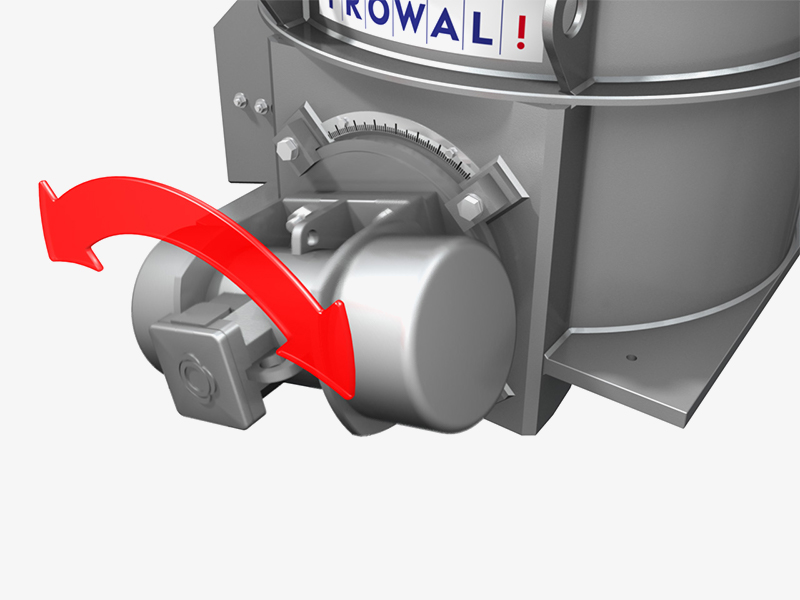

Automatic Emptying Of The Work Bowl

After processing your work pieces the abrasive media must be removed from the work bowl. This is done via a pneumatic outlet, which is located at the bottom of the work bowl and is available as an option. The outlet can be operated or controlled either via a manual control system or via a PLC. With fully automatic operation by PLC, a safety device is provided to protect the operator. The machine stops before the outlet opens automatically after a preset time has elapsed. After the outlet is fully opened, the machine is restarted and the work bowl contents are discharged completely into a provided loading trolley. This means that your operator can carry out set-up work during this time, as the manual opening of the plug in the work bowl outlet is no longer necessary.

Work bowls with optional pneumatic outlet are equipped with a screen outlet at the rear through which the process water can drain off during processing.

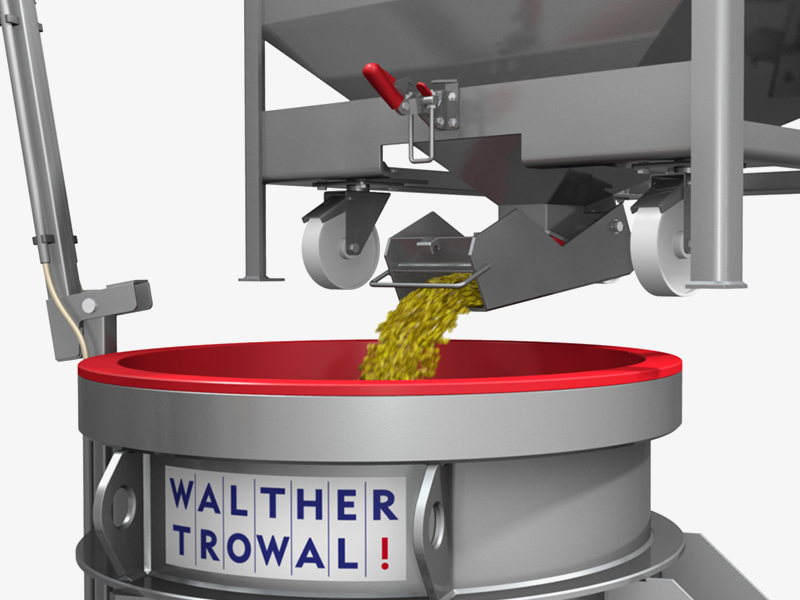

Fully Automatic Vibratory Finishing Process Of The MV 50

With our largest model, the MV 50, we offer a fully automatic machining process. After the abrasive media have been discharged automatically from the work bowl and after your work pieces have been exchanged (machined for unmachined), the abrasive media are fed back into the machine via a bunker and conveyor belt system and the process can start again.

The benefits at a glance

- High reproducibility

- Uniform finish

- Wet process with water and compound

- Suitable for 24-hour operation

- Low fitting and auxiliary process times with electromagnetic clamping device

Put us to the test

Do you want to test whether the multivibrators are suitable for your needs? Then we would be happy to offer you advice in the Technikum, our in-house laboratory. Together, we can determine in advance the process and performance-related parameters so that we can give you a multivibrator that perfectly meets your requirements. Feel free to get in touch!