Blasting technology

Innovative work piece transport system guarantees optimal blast results

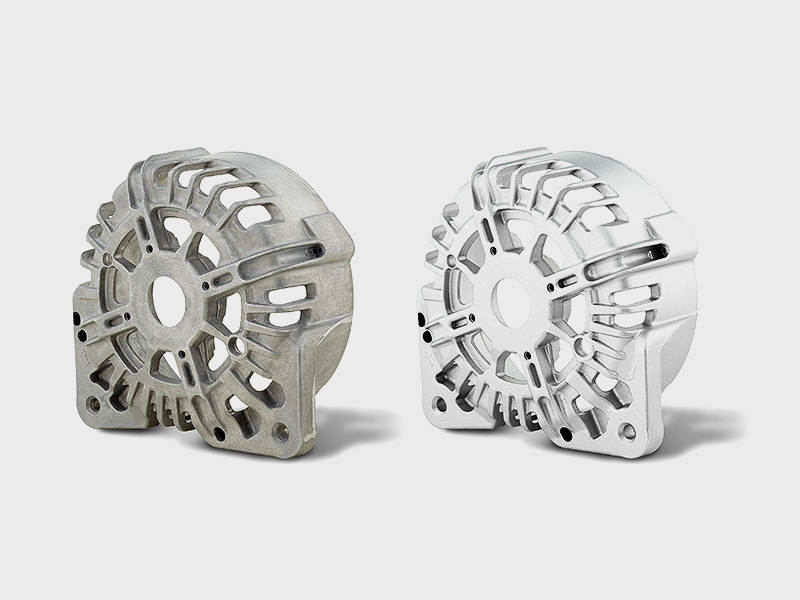

Shot blasting creates an appealing, highly homogeneous surface appearance. It also removes flashes from die-castings, descales and de-rusts work pieces and even induces a compressive stress in the work piece surface. So-called blast turbines accelerate the blast media to speeds of up to 100 m/sec. This creates a high impact energy on the work piece surface.

Blast turbines generate a high blast media throughput. This guarantees short cycle times and a high blasting efficiency.

With our innovative continuous feed troughed belt work piece transport system we have set a high technological standard: It generates not only a high blast intensity but also transports the work pieces gently through the blast machine. Since the work pieces are continuously tumbling, they receive an all-around, intensive exposure to the shot blast media.

The result: The work pieces are leaving the shot blast machine with an excellent surface finish.

Depending on the application and work piece material, blast media made from stainless steel, aluminum or brass are utilized.