Aerospace Industry

Aerospace components require a lot more than just a shiny surface: The safety of the flight operations and the efficiency of the jet engines are the dominating factors. For this reason, the quality requirements for the surface finish of structural, landing gear and jet engine components are especially high.

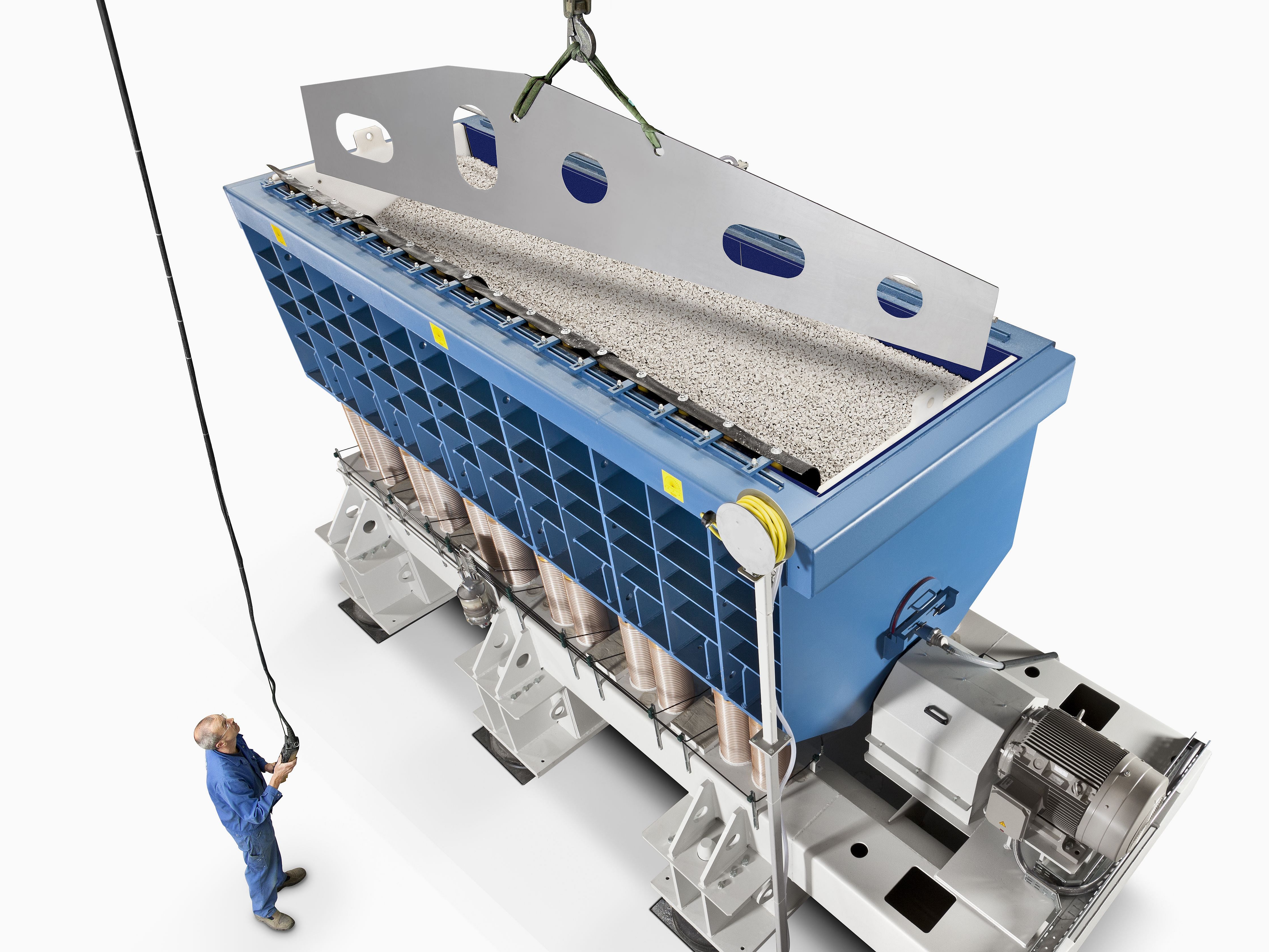

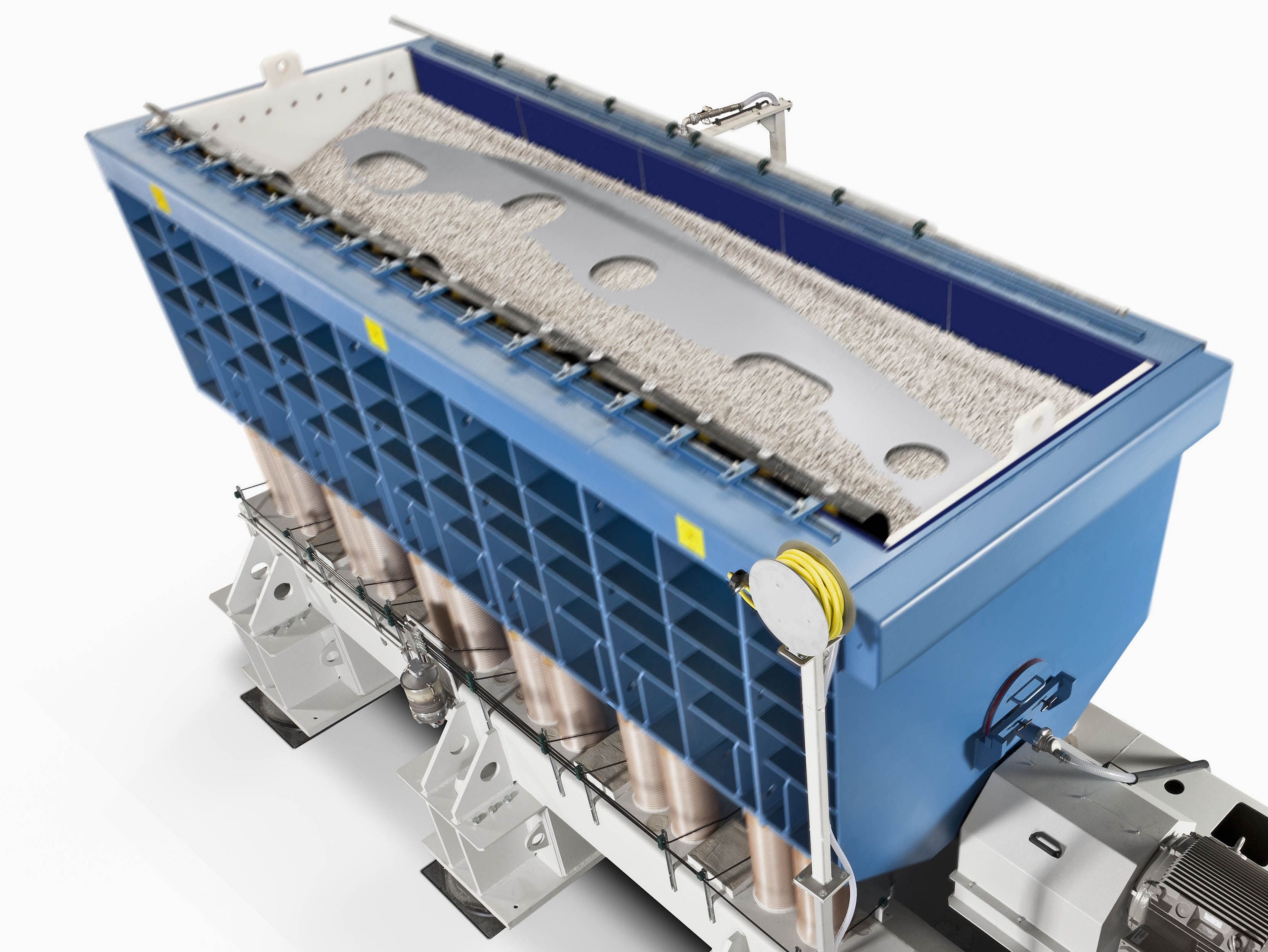

The Walther Trowal mass finishing machines have been especially designed to meet the stringent surface requirements of the aerospace industry: They produce not only the desired surface finishes but also ensure that even the tightest manufacturing tolerances are precisely met batch after batch.

Moreover, in compliance with international standards and guidelines, the Walther Trowal processes, media and compounds are approved for numerous surface finishing operations in the aerospace industry.

Structural components

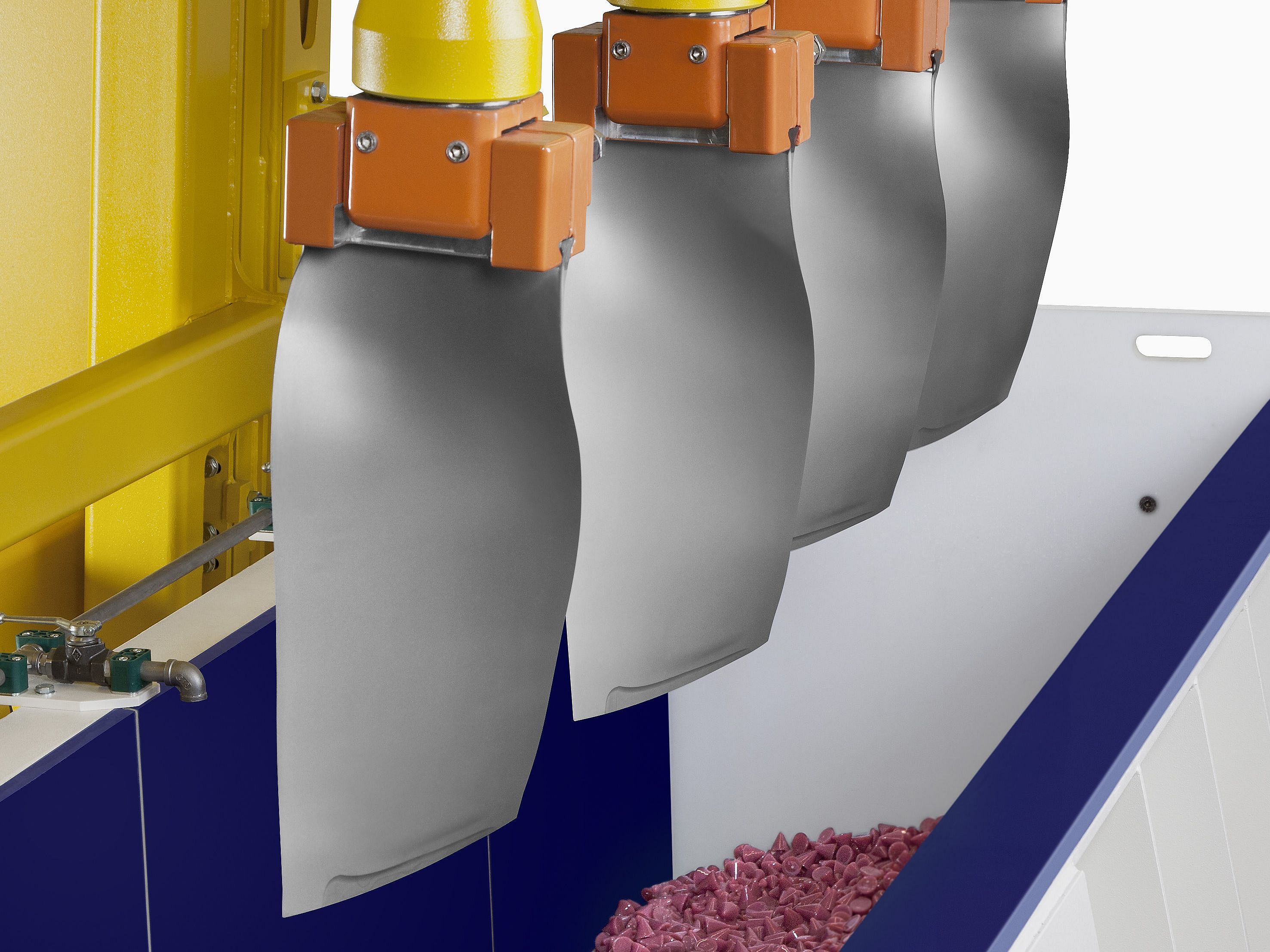

Fuselage and wing components, for example wing spars or stringers, often have a length of several meters. For these components the Trowal tub vibrators offer excellent finishing solutions.

Landing gears

Landing gear components like housings, linkages, brakes or wheels, are usually subject to different surface finishing requirements. For this reason, we provide shot blasting and mass finishing solutions, which produce the required results, be it deburring, edge radiusing or the surface treatment of internal passages of complex components. Jointly with the customers our experts will develop the ideal finishing solution

Jet engines

Engine components – compressor and turbine blades, rotors and housings –require mostly a defined surface smoothing and precise edge radiusing. Walther Trowal mass finishing machines furnish the solution: They produce the specified surface smoothness and edge radiusing without negatively affecting the geometrical integrity of the components. The result: A higher operational efficiency, less fuel consumption and significant noise reduction.

For the processing of blisks (bladed disks) Walther Trowal developed a special rotary vibrator that allows the deburring and surface smoothing of components with a diameter of up to 980 mm. Compared to manual finishing this machine reduces the overall processing time from several days to a few hours.

Small mass produces components

For coating of small airplane components like screws, springs, rivets or control keys, many suppliers are successfully utilizing the Trowal Rotamat batch coating systems.

Sales Manager