Medical engineering

Quite a few work pieces for medical applications are subject to the most stringent surface finishing requirements. Their surface must not only be very smooth, but their dimensions – especially in the case of endoprosthetic implants – must precisely comply with the specifications. The tiniest surface irregularities or scratches can require a component to be scrapped.

Particularly, when it comes to complex implants exposed to high mechanical loads – for example, knee femorals -- the material removal during the grinding and polishing stages must be even on all surface areas. This ensures an optimum fit during implantation.

Mass finishing

For deburring of the work pieces, for edge radiusing, surface smoothing and polishing we can offer finishing solutions that meet the specific customer requirements.

Especially with materials frequently used in medical engineering like stainless steel, titanium, cobalt chrome alloys or ceramic, our experts can offer years of experience.

We have also developed solutions for 3D printed medical components like knee implants, dental wire braces, teeth aligners or ear adapters for hearing aids.

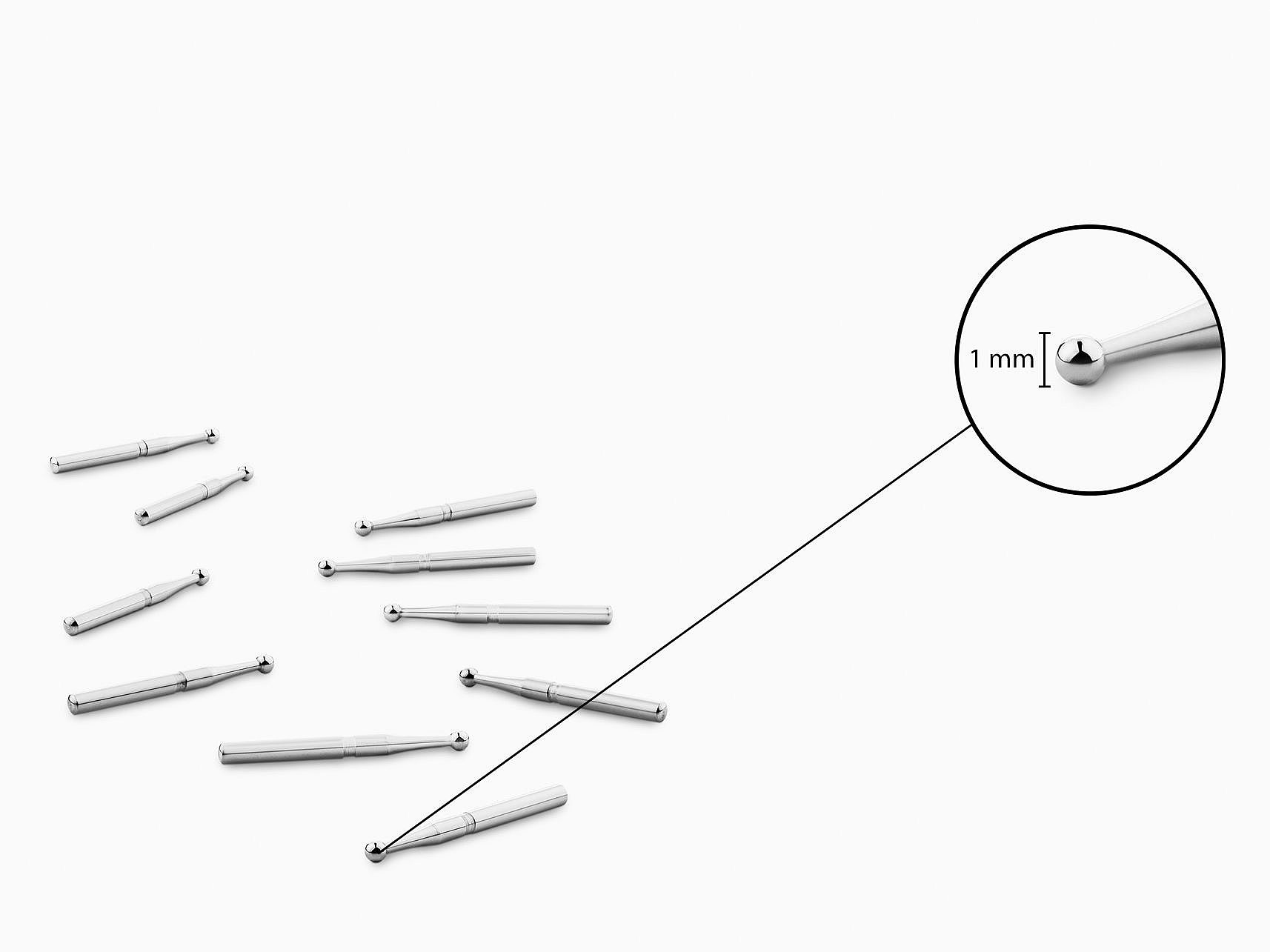

Further examples are the polishing of surgical instruments, the targeted deburring and edge radiusing of bone screws and bone plates or the high gloss polishing of hip and knee implants. Even small dental drill bits can be safely finished in our machines.

Our systems are also utilized for creating high gloss finishes on ceramic components, which to date were considered impossible. For example, such perfect finishes significantly increase the service life of implants.

Coating

Our Rotamat coater is the ideal solution for coating of small medical components produced in high volumes like, for example, the housings of hearing aids.

Sales Manager