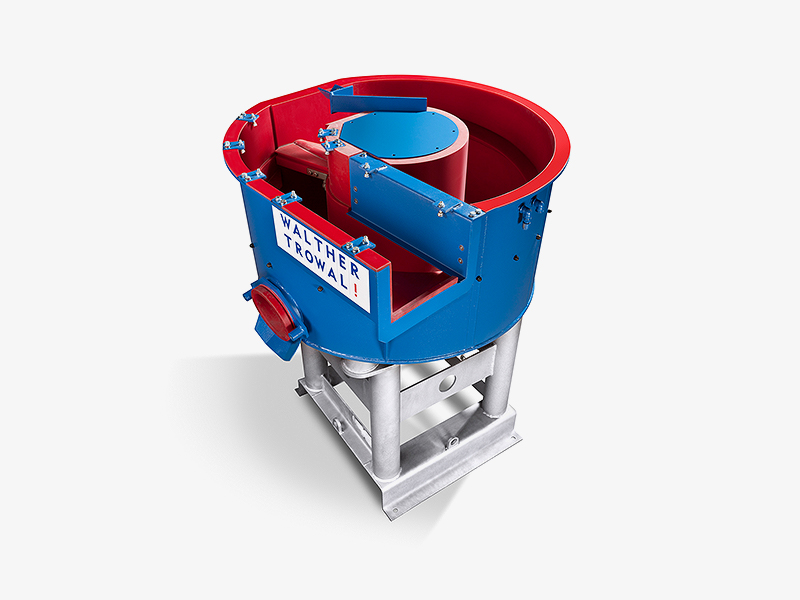

Polyurethane lining – Durable and robust

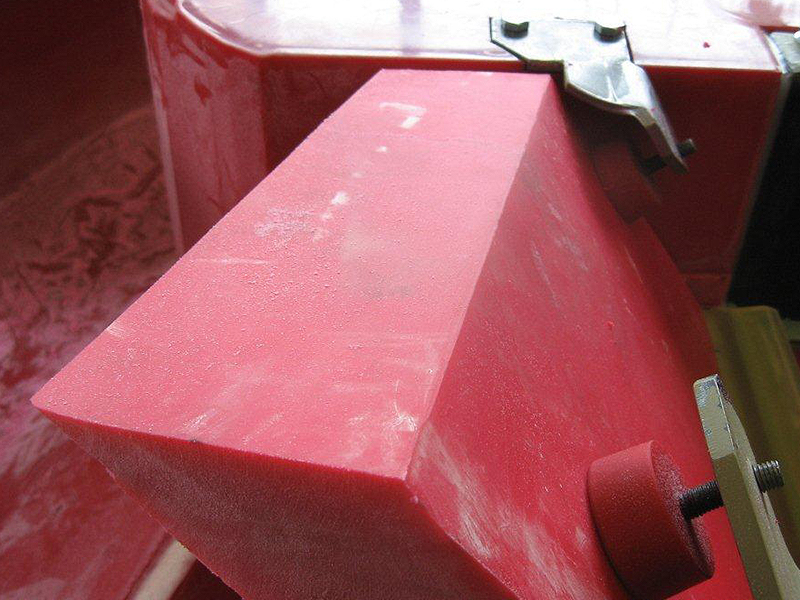

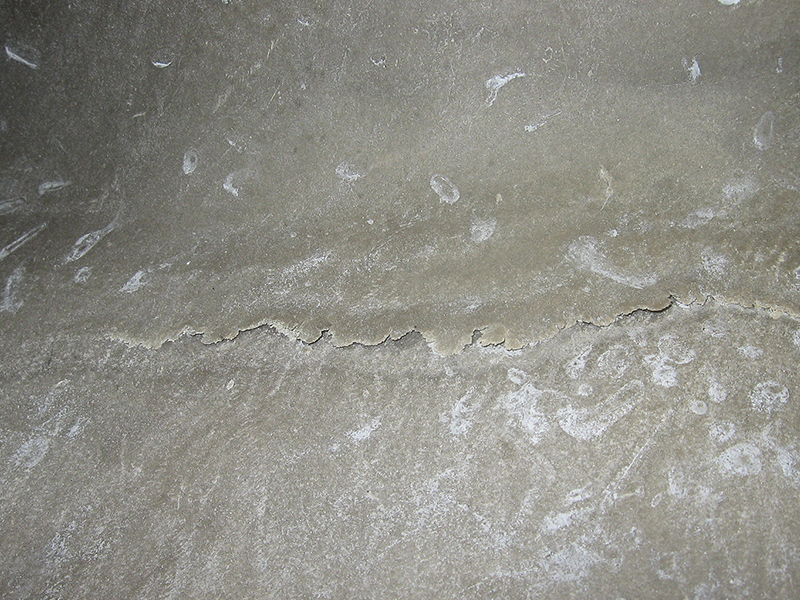

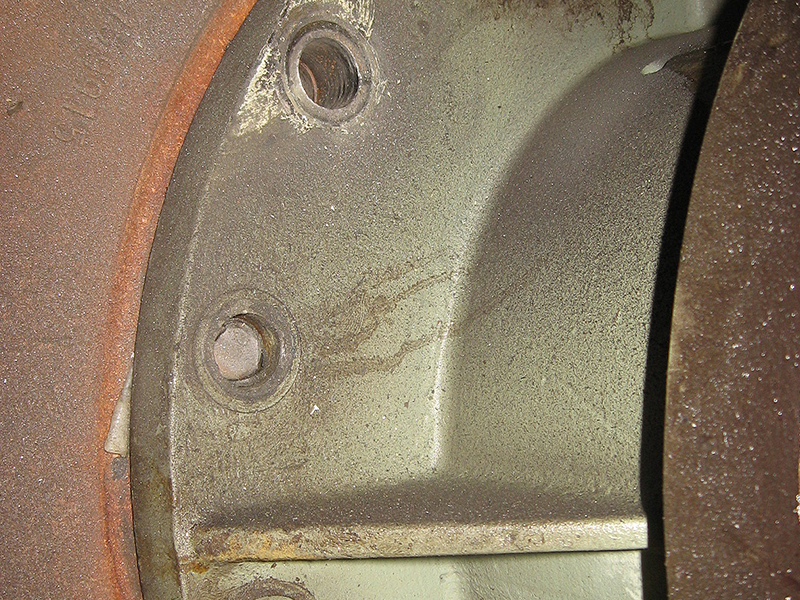

The abrasive media used in mass finishing processes abrade not only your workpieces, but also the work bowl. That is why the steel bowls of our mass finishing systems are protected with a polyurethane lining that is particularly resistant to tears. But even this elastic tear protection needs replacing from time to time.

Making used mass finishing bowls as good as new

Replacing the lining should be as easy as possible, in order to minimise downtimes. If your work bowl is worn, contact TROWAL SERVICE. Using an existing replacement bowl, we produce a duplicate of your product, fit a new lining and deliver to you. Your worn bowl is then re-used as a replacement component.

The benefits at a glance

- Worn component made as good as new, with manufacturer guarantee

- Tested and expertly repaired steel construction with no nasty surprises

- Low downtimes

- Lining made from high-quality polyurethane, poured and correctly tempered under manufacturing conditions

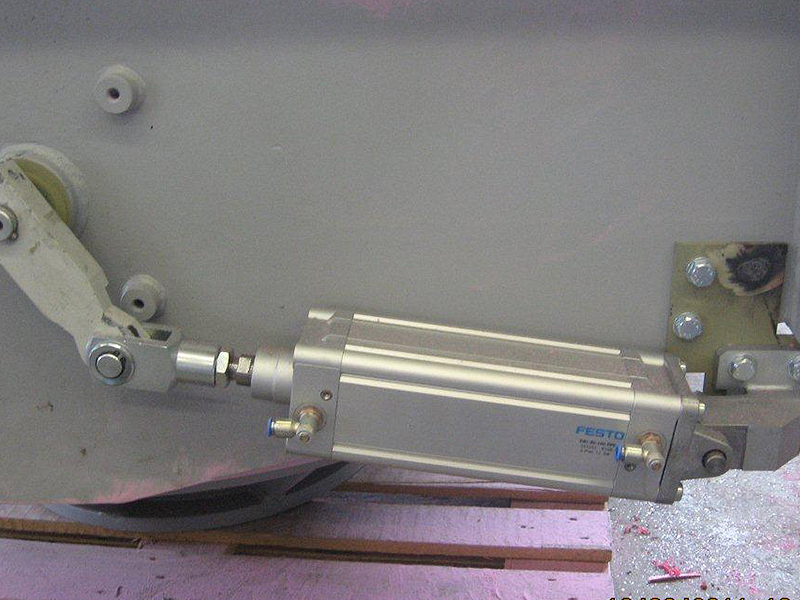

- New separation device (separator flap with control) if on original

Your contact partner