At the DKT 2022 exhibition Walther Trowal introduces the new generation of the R 85 Rotamat system for coating mass-produced small parts made from elastomers. Equipped with new spraying technology, precise volume control and integration into the data environment of the users, this coater is ideal for coping with the most challenging coating jobs

New, externally controlled automatic spray guns are evenly applying the coating material onto the surface of the elastomer components. A new sensor continuously measures the material flow with an accuracy of 1/10th gram per minute. This guarantees that the desired amount of coating material is applied onto the surface during the entire process. And it ensures that the desired coating thickness is precisely and consistently achieved.

This makes the Rotamat systems ideally suited for the coating of delicate parts with complex shapes and for tasks, where process safety and consistency are key requirements. Examples for such challenging tasks are coating jobs with two-component coating materials containing pigments or the application of solvent-based lacquers, which must meet particularly stringent quality standards.

A communication processor allows the integration of the Rotamat coaters into higher level production control systems and the industry 4.0 environment of the customers. It also permits the detailed documentation of the entire coating process

Frank Siegel, the sales manager for coating technology at Walther Trowal, explains: „In our new Rotamat 85 system the coating process is now based on precisely measured data. This represents not only a significant improvement of the actual coating operation, but it also is a tremendous help for audits: Our customers can now prove at any time that their production is characterized by a high process safety and consistency of the coating results

Walther Trowal at the DKT 2022 exhibition

June 27 – 30, 2022 in Nuremberg/Germany

Hall 9, Booth number 314

Background information

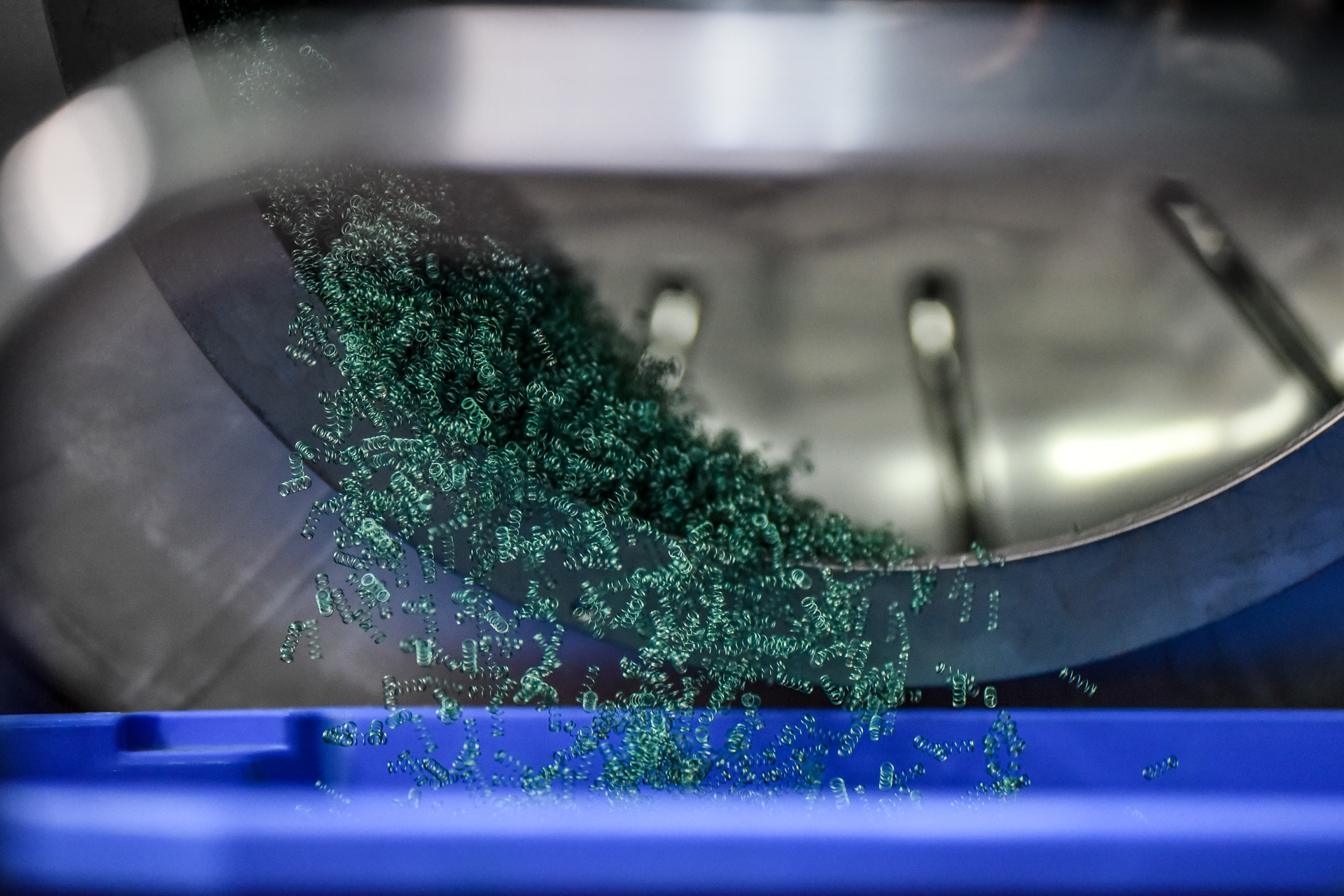

Rotamat systems represent a highly cost-efficient solution for the coating of mass-produced small parts, such as O-rings, handles, springs, or screws. They can be used for a broad range of components made from metal, wood, rubber, or all kinds of plastic.

This includes components for the automotive and cosmetics industry, for toys, stationary goods, and furniture parts as well as seals and shock absorbers. Water- as well as solvent-based lacquers can be processed.

Rotamat systems are equally effective for decorative and functional coatings with numerous water- and solvent-based lacquers as well as for coatings with anti-friction substances, primers, corrosion materials or insulating lacquers.

In Rotamat systems the small parts are coated in a closed, rotating drum. Automatic spray guns are evenly applying the coating material onto the surface of the work pieces, while these are continuously tumbling over each other. The parts are simultaneously dried. This results in an evenly coated surface, a precise coating thickness and a high long-term stability of the coating.

Even delicate components with complex shapes are leaving the machine with an even coating, in single pieces and completely dry! They can be immediately processed in downstream manufacturing operations

The coating process runs fully automatically. All the operator must do, is loading and discharging the drum. The time-consuming and complicated placement of the components on racks, as required with conventional coating systems, is no longer needed.