Haan, Germany, September 10, 2018 At the ALUMINIUM 2018 exhibition Walther Trowal presents its new process for the gentle surface finishing of guide vanes used in turbines and compressors. It creates very smooth surface readings and, thus, optimizes the airflow through the guide vanes.

After they have been milled from a cast block of aluminium, guide vanes for turbines or compressors require a very smooth surface to insure optimum airflow around every single blade. To date this required a complex and costly mechanical process.

Walther Trowal has recently developed a method that allows the gentle smoothing of the guide vanes after milling without rounding the leading edges beyond the acceptable tolerances – an important factor for increasing the efficiency of jet engines.

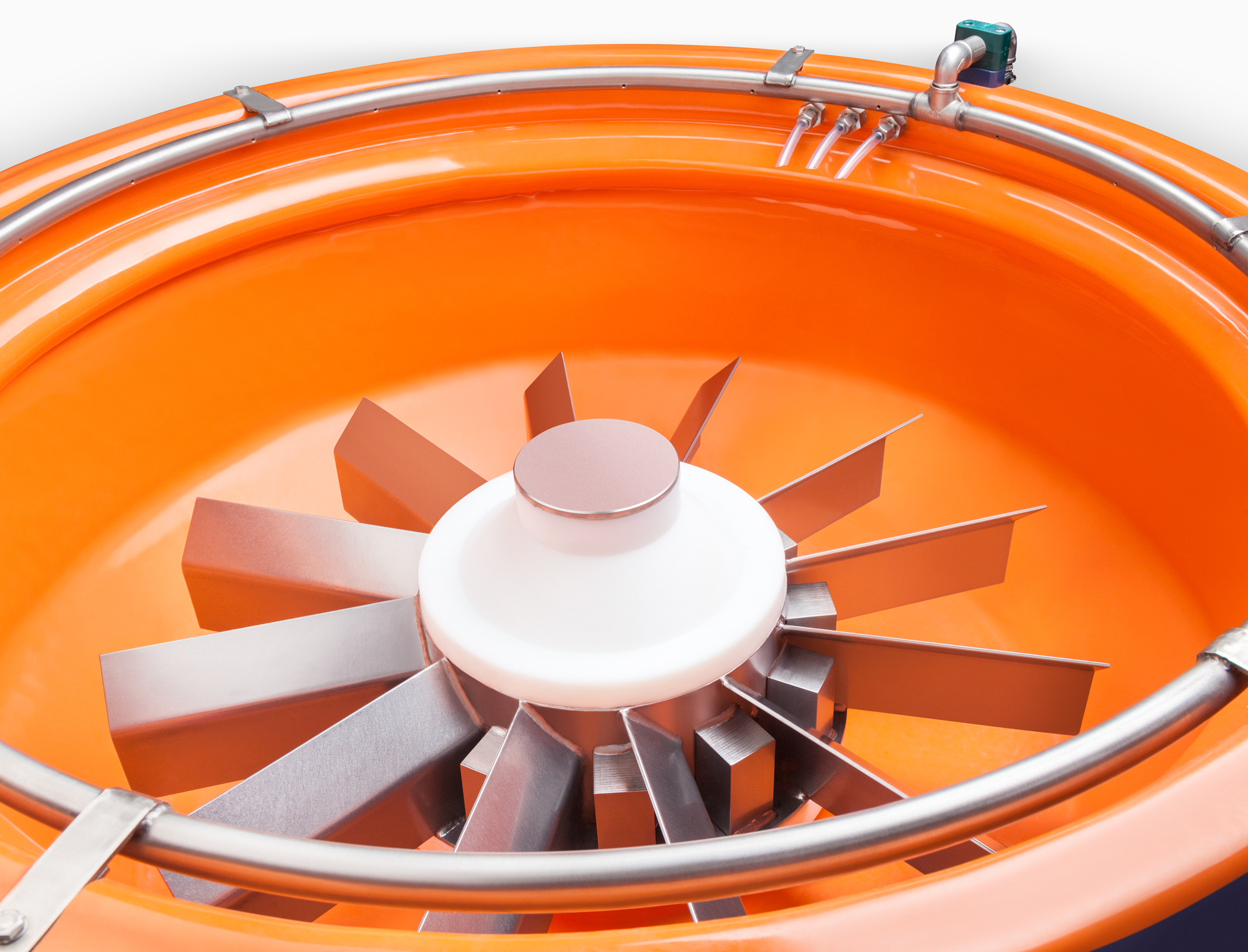

Basis for the new process are the rotary multi vibrators of the model range MV allowing the processing of guide vanes with diameters of up to 800 mm. The company utilizes special, extremely small ceramic grinding media, which provide not only optimum surface coverage on the work pieces but also smoothens the surface at the root of the vanes.

The guide vanes, but also blisks, are mounted to a fixture that is magnetically attached to the base of the processing bowl. This ensures that the overlapping, high-frequency vibrations from the multi vibrator are transferred to the work piece, causing intensive contact between the media and the vane surface areas.

The result of the fully automatic finishing process: The milling lines from the preceding machining step have been ground out creating a very smooth surface. With the new process Walther Trowal reduces the Ra surface readings from 4.0 down to 1.0 µm with only minimal rounding of the leading edges. This innovative mass finishing process creates ideal conditions for an optimum airflow through the guide vanes.

At the ALUMINIUM 2018 Walther Trowal also presents rotary vibrators used for the surface finishing of aluminium castings including the removal of burrs.

320 words including introduction

Walther Trowal at ALUMINIUM 2018

Düsseldorf, September 18 – 22, 2018

Hall 12, Stand G50

Contact: Walther Trowal GmbH & Co. KG | Contact for the editor: VIP Kommunikation |

Photos

Photo1: The MV multivibrators are equipped with high-speed imbalance motors. The overlapping high-frequency vibrations create very fine, homogeneous surface finishes. File name: | |

Photo 2: Blisks for jet engines – the photo shows a dummy part – can also be processed in rotary vibrators, producing excellent finishing results. File name: |

Copyright photos: Walther Trowal

Facts about Walther Trowal

For 85 years Walther Trowal has been a pioneer and market leader in various surface treatment technologies. The company offers modular and custom engineered solutions for a wide range of surface treatment problems.

Initially only making vibratory finishing equipment, over the years Walther Trowal has continuously broadened its product range and today offers a wide portfolio of equipment and services for improving all kinds of surfaces, e.g. mass finishing, part cleaning, shot blasting and drying of a wide spectrum of work pieces, last but not least, the coating of mass produced small parts.

Walther Trowal offers not only various types of equipment but complete surface treatment systems: By linking the various equipment modules and automating the complete process, we are able to precisely adapt our process technologies to the technical requirements of our customers. This also includes various types of peripheral equipment and process water cleaning and recycling systems. Of course, we also offer comprehensive pre- and after-sale service like sample processing in one of our demonstration labs and global repair and maintenance service.

Walther Trowal serves many customers in many industries around the world. For example, in the automotive and aerospace industry, medical engineering and wind power generation.