Haan, Germany, April 11, 2019 At the GIFA 2019 exhibition Walther Trowal introduces the compact troughed belt continuous shot blast system THM 300/1 to the public. This machine was especially developed for processing high volumes of small, delicate work pieces. The new design combines the small footprint of batch machines with the advantages of continuous feed operation and, thus, helps streamline and speed up the blast cleaning processes for small castings.

Walther Trowal developed the THM 300/1 specifically for small, delicate or thin-walled cast work pieces like, for example, aluminum or zinc die-castings with diagonal dimensions of between 20 and 150 mm (about 0.8 to 6.0”). Work pieces can range from components for toys (model cars and trains), furniture parts, components for the computer industry and even small automotive parts.

For the first time a shot blast machine for processing small work pieces is available with the footprint of a batch tumble belt machine that permits, however, continuous feed operation. Compared to the smallest THM machines supplied to date by Walther Trowal, the THM 300/1 design is considerably more compact: It requires an area of only 1,4 × 2,7 m (5 x 9 feet) and can, therefore, be easily integrated into existing production lines.

With this new machine concept Walther Trowal meets the demands of customers in the foundry industry, who want to integrate their blast cleaning operations seamlessly into already existing manufacturing lines.

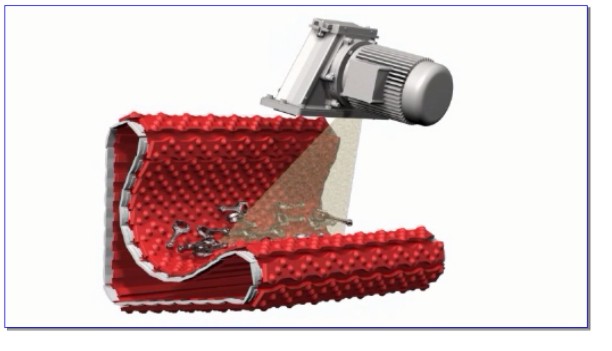

The troughed belt work piece transport system Walther Trowal is utilizing for its continuous shot blast machines is gently moving the work pieces through the machine in a spiral motion. This ensures that all work piece surface areas are equally exposed to the blast media stream.

Meik Seidler, sales manager at Walther Trowal, recognizes a significant trend towards continuous shot blasting: „The THM continuous feed machines with their unique troughed belt work piece transport system are more and more displacing the conventional batch tumble belt machines. Our customers integrate the THM systems into linked manufacturing processes allowing them to significantly simplify the work piece handling. The work pieces are continuously fed into the machine at preset cycle times determined by the actual production volume. Intermediate transport operations from one process stage to the next, as well as intermediate storage, are completely eliminated.”

For the new blast system Walther Trowal is using the newly developed WTY turbines with curved throwing blades. Compared to conventional blast turbines they generate a substantially higher throwing speed. This increases the impact energy of the blast media on the work pieces, which in turn helps reduce the processing times.

A communication processor allows integrating the shot blasting operation into higher-level process controls. Explosion protected dust collectors ensure safe operation in line with prevailing explosion prevention standards.

2,700 characters

Walther Trowal at GIFA 2019

Düsseldorf, June 25 – 29, 2019: Hall 15, booth D 15

Background information:

Troughed belt continuous shot blast machines guarantee gentle work piece transport

The THM troughed belt continuous shot blast machines from Walther Trowal are equally usable for mass produced bulk parts as well as for delicate individual components with complex shapes. Because of their simplified work piece handling and superior shot blast results they are more and more displacing conventional batch tumble belt machines.

The THM continuous shot blast machines are especially advantageous for processing delicate work pieces: The parts in the trough are not colliding with each other from relatively high dropping heights but are passing through the machine with a gentle rolling movement. The transport rods are covered with a polyurethane lining, which further protects the work pieces from getting damaged or nicked. Since there is a technological trend towards more delicate components, which must be blast cleaned, the gentle work piece transport through the shot blast machine is especially important. The Walther Trowal troughed belt transport system makes sure that the work pieces are passing through the machine without getting damaged.

For somewhat larger work pieces with complex shape the troughed belt machine concept also produces better blast cleaning results than spinner hanger shot blast machines: While passing through the trough the work pieces are continuously rotating. This ensures that the blast media is reaching all work piece surface areas, and always from the same distance. The result: All-around highly homogeneous shot blasting results.

Background: 1,100 characters

Contact: Walther Trowal GmbH & Co. KG | Contact for the editor: VIP Kommunikation |

Photos

Photo 1: The compact troughed belt continuous shot blast system THM 300/1 combines the small footprint of batch machines with the advantages of continuous feed operation File name: | |

Photo 2: The troughed belt blast machine THM 300/1 is ideal for continuous feed blast cleaning of small work pieces. To demonstrate the work piece variety this machine can handle, for the photo different components were placed on the troughed belt.

File name: | |

Photo 3: The troughed belt principle: The work pieces are gently rolling over the transport rods equipped with a polyurethane lining. They do not collide but are passing through the machine by gently touching each other. File name: |

Copyright for the photos: Walther Trowal

About Walther Trowal

For 85 years Walther Trowal has been a pioneer and market leader in various surface treatment technologies. The company offers modular and custom engineered solutions for a wide range of surface treatment problems. With more than 12,000 machines installed at customer locations the inventor of the vibratory finishing technology is a global leader in the field of surface treatment.

Initially only making vibratory finishing equipment, over the years Walther Trowal has continuously broadened its product range and today offers a wide portfolio of equipment and services for improving all kinds of surfaces, e.g. mass finishing, part cleaning, shot blasting and drying of a wide spectrum of work pieces, last but not least, the coating of mass produced small parts.

Walther Trowal offers not only various types of equipment but complete surface treatment systems: By linking the various equipment modules and automating the complete process, we are able to precisely adapt our process technologies to the technical requirements of our customers. This also includes various types of peripheral equipment and process water cleaning and recycling systems. Of course, we also offer comprehensive pre- and after-sale service like sample processing in one of our demonstration labs and global repair and maintenance service.

Walther Trowal serves many customers in many industries around the world. For example, in the automotive and aerospace industry, medical engineering and wind power generation.