CB circular vibrators

Efficient mass finishing for the toughest requirements

With a circular vibrator from our CB range, you get a mass finishing machine that works efficiently and achieves perfect processing results. The working channel is helically shaped and allows you to gently process your workpiece whilst ensuring high material abrasion.

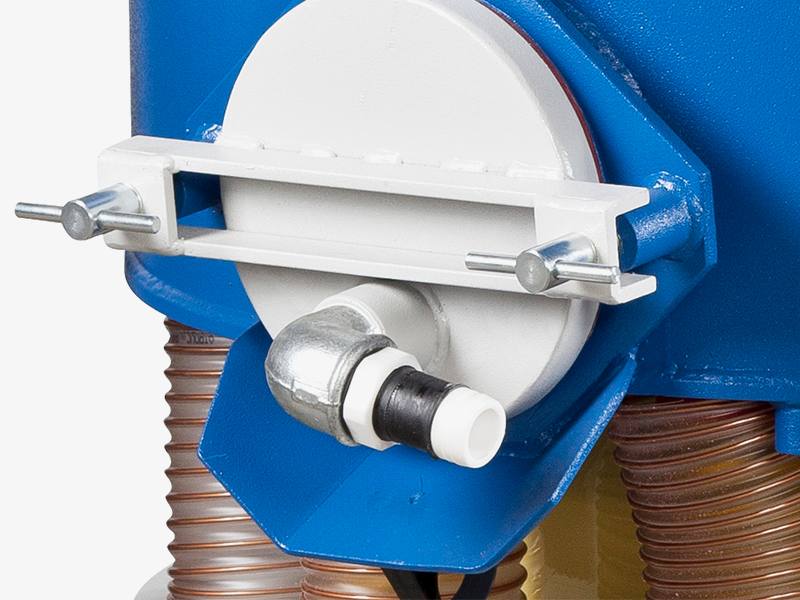

Gate clearing at the push of a button

By pressing a button on the unit, you can quickly reverse the motor's direction of rotation before separating your workpieces from the abrasive media. This ensures that no workpieces or abrasive media are left on the gate that could get trapped between the separator flap and the working channel.

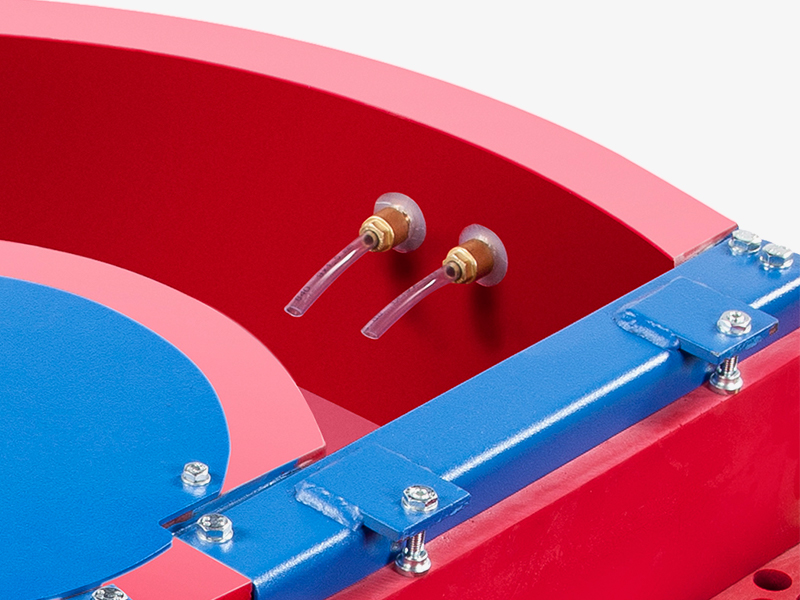

Ideally suited for ball burnishing and pressure deburring

The CB circular vibrators stand out thanks to their robust steel construction and reinforced imbalance drive in the ball burnishing configuration. This makes them ideal for ball burnishing and pressure deburring with blasting medium.

The benefits at a glance

- Helically shaped working channel

- Integrated screening unit

- Gate clearing via a button on the machine

- Reinforced imbalance drive in ball burnishing configuration

Application Images

Sales Manager

Jochen Bergmann

Mass finishing, process water and blasting technology sales

+49 (0) 2129 571-225