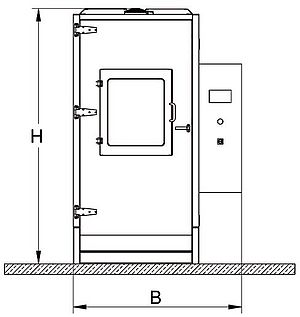

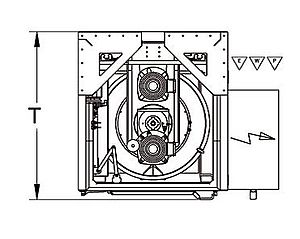

M-TMD

A highly efficient method without the risk of work pieces damaging each other

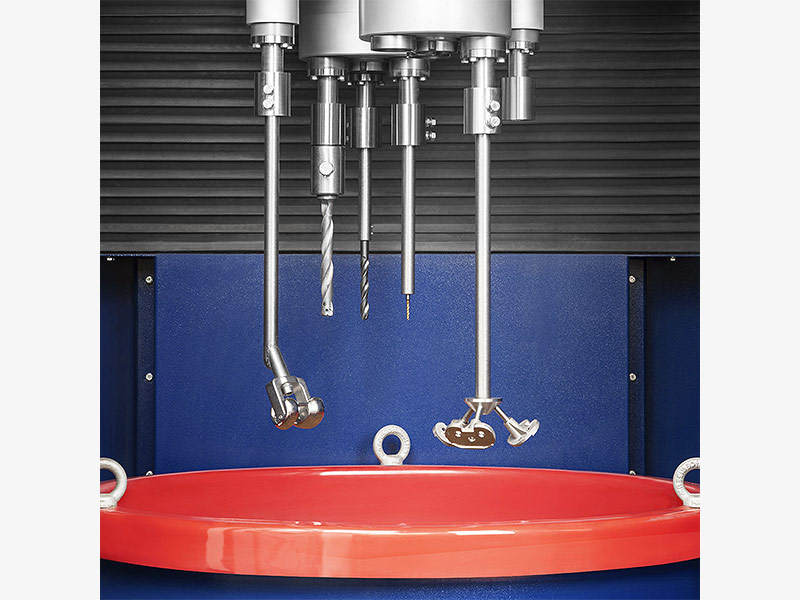

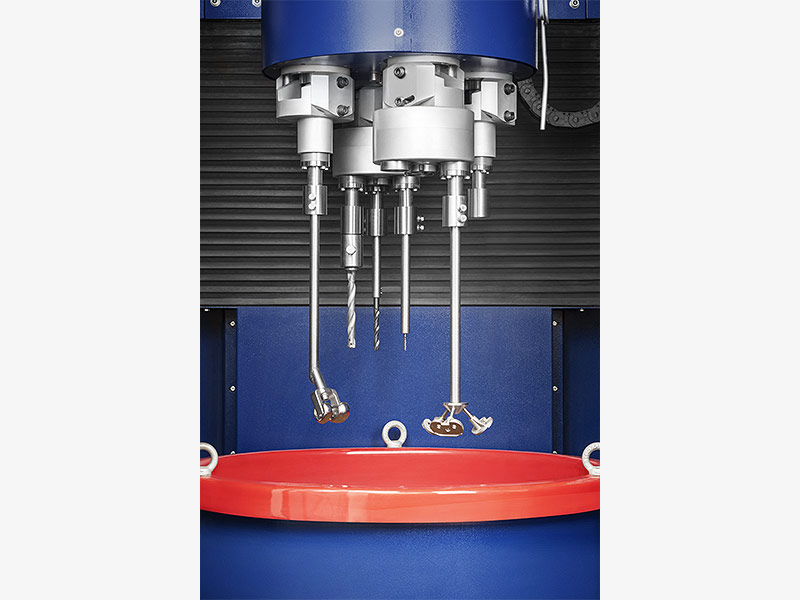

Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement.

Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results.

Applications:

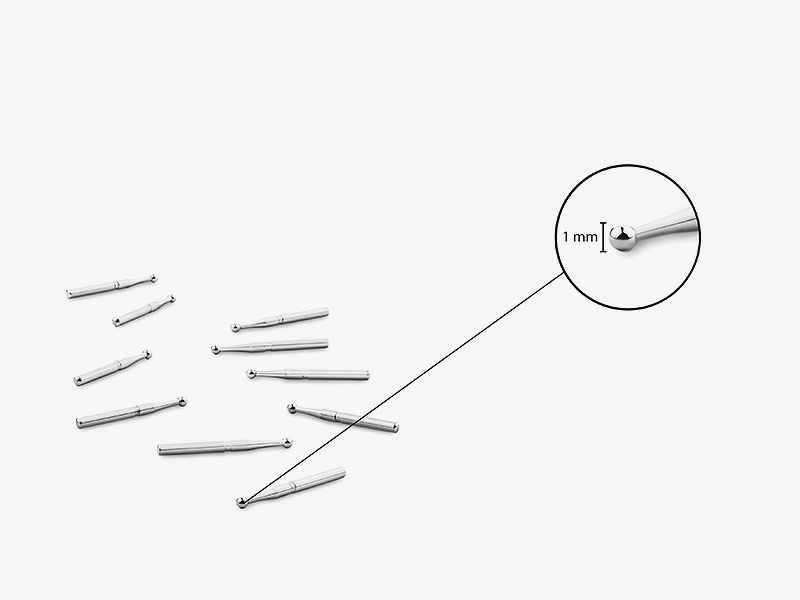

- Orthopedic implants (medical engineering)

- Turbine blades (for airplanes as well stationary turbines)

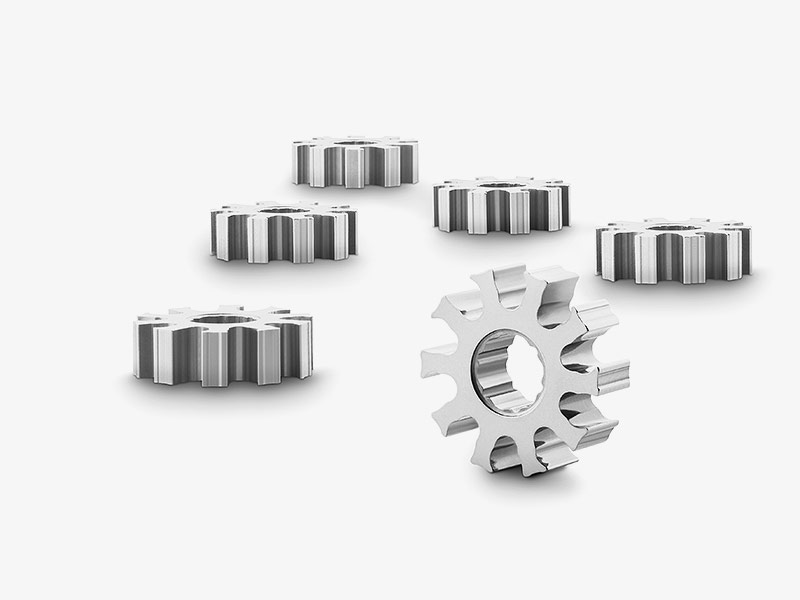

- Precision components, for example, for pumps and compressors

- Work pieces made from tungsten carbide and other hard metals

- Fan wheels for turbo chargers (automotive industry)

- Sintered components, etc.