TFM vibrators

Robust, cost effective and versatile

With a trough vibrator from our TFM range, you get a mass finishing machine that can trowalize large and sensitive parts as required. Alongside an excellent processing result, this machine stands out above all thanks to its great-value purchasing costs. The bowl can also be supplied with a rubber lining.

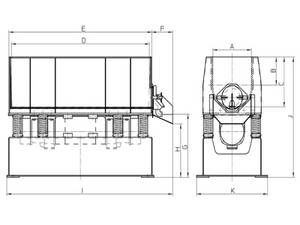

U-shaped work bowl

TFM vibrators are supplied as standard with U-shaped work bowls with straight walls, which can also be ordered with integrated wedge profile for better mass circulation.

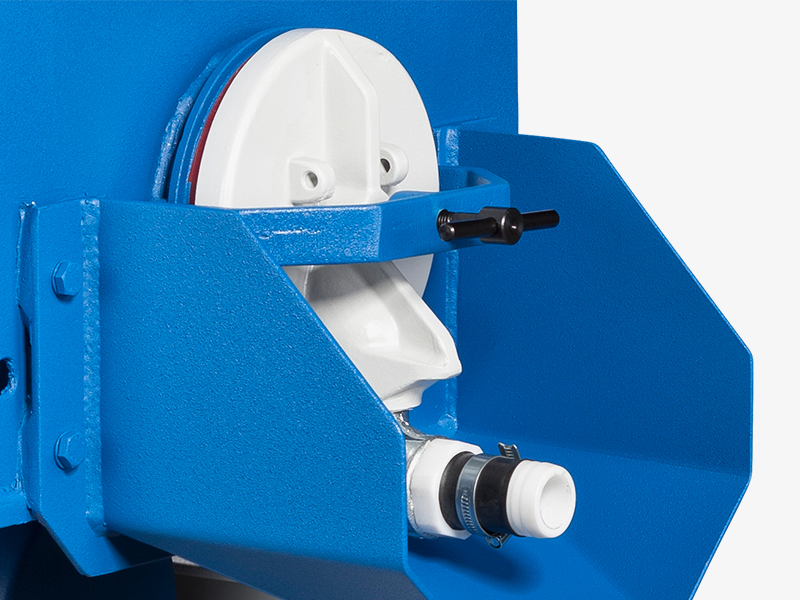

Vibration via conventional imbalance motors

Powerful conventional imbalance motors generate the imbalance in the trough vibrators. Your TFM vibrator will have one or two imbalance exciters depending on its size.

Perfect for ball burnishing and pressure deburring

The smaller models in the series have a reinforced work bowl, a more powerful drive and an acid-proof lining. This makes them ideal for ball burnishing and pressure deburring with blasting medium.

The benefits at a glance

- Available with optional rubber lining

- Trowalize large and sensitive parts

- Powerful conventional imbalance motors

- Ideal for ball burnishing and pressure deburring