CF circular vibrators

Our entry-level model – Efficient and cost effective

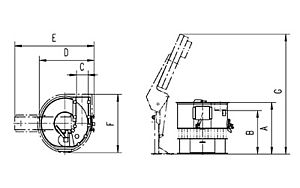

The circular vibrators of the CF series are a perfect and simple introduction to mass finishing. The seven different configurations, with a range of different bowl sizes, offer excellent efficiency and maximum cost effectiveness. The CF circular vibrators are easy to operate and can be expanded with accessories for sound deadening or metering, for example.

Processing and separation – Smooth mass finishing

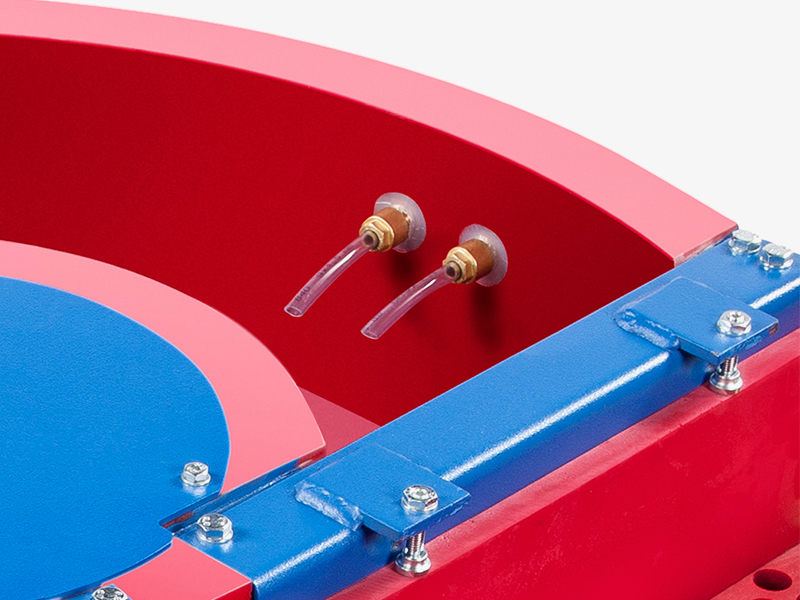

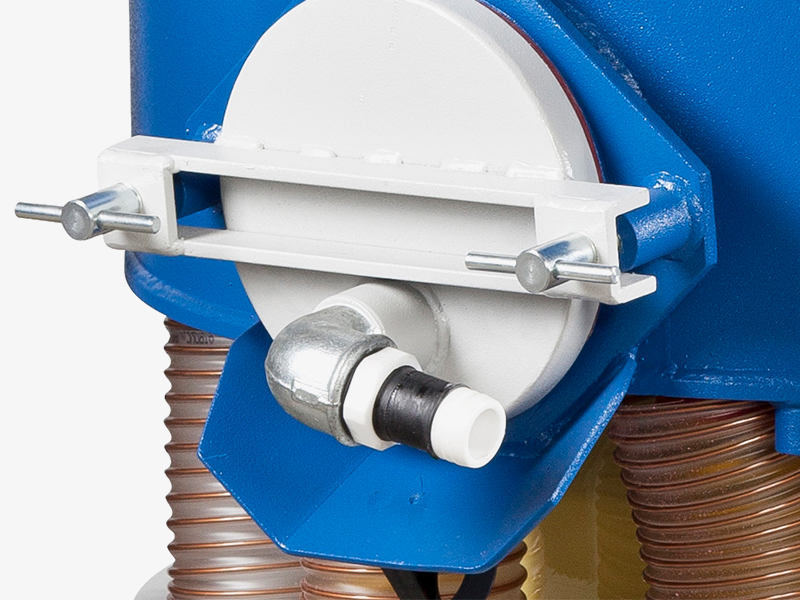

The work bowl with an evenly rising floor is perfect for processing your workpieces, as the zero-maintenance vibration flange motor works at two different speeds. The pneumatic separator flap and long separation zone allow you to gently separate your workpieces from the abrasive media. This creates a smooth mass finishing process with excellent results.

The benefits at a glance

- Integrated screening unit

- Pneumatically operated separator flap

- Zero-maintenance vibration flange motors

- Two-speed drive

- Bowl sizes from 100 to 1,200 litres

- Available accessories: sound deadening lid, metering unit, magnetic separator, vibration dryer