Vibratory finishing, also known as mass finishing, barrelling and rumbling is based on processes in nature. Here, sand and water grind down rough blocks of stone to smooth, perfectly rounded pebbles. What we do in modern manufacturing technology is no different. With the right combination of machine, abrasive media, compound and water, we can perfect virtually every surface precisely to your requirements, using processes ranging from mass finishing, deburring, polishing and descaling to cleaning, smoothing and rounding.

Trough vibrators

If your workpieces are too large for circular vibrators, simply process them individually in the trough. Sensitive parts can be secured or processed in separate chambers.

to overview

Continuous units

Our continuous units can be installed to continuously process your workpieces in the production process. The individual parts are added to the mass finishing machine in cycles, without interrupting the process.

to overviewquick entrance

AV unit

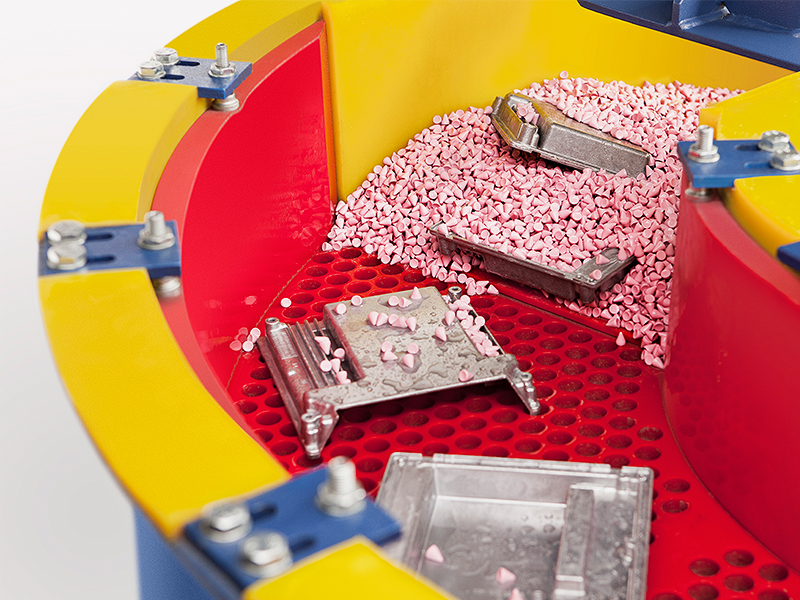

Centrifugal disc finishing units

Centrifugal disc finishing units have an abrasive action that is ten times stronger than that of circular vibrators. This helps remove heavy burrs and round off edges on small and medium workpieces.

to overview

Circular vibrators

From deburring and rounding to high-gloss polishing, circular vibrators can be used anywhere.

to overview

Media and Compound

The right combination of process media can ensure the perfect processing results. Ceramic and plastic abrasive media, combined with compounds and special media, create the ideal surface.

to overview

Drums and rotating barrels

Drums and rotating barrels are the cost-effective solution for processing small workpieces – such as those in precision mechanics – in small and medium batch sizes. They are also suitable for fine finishing and polishing.

to overview

Dryers

After mass finishing, workpieces are generally wet or moist and must be dried. This is done using either a heated drying medium or hot air, depending on your individual needs.

to overview

Accessories

Our wide range of accessories can help you adjust circular vibrators, trough vibrators, continuous units and all other processing systems to your individual requirements, and help you improve your processes.

to overview

Process water technology

Effective and efficient, reusing process water (a mixture of water and compound) and feeding it back into circulation during mass finishing can help you both save costs and protect the environment.

to overview

Drag finishers

High-value, delicate work pieces with complex shapes or work pieces made from tough, difficult to machine materials are mounted to special fixtures and dragged through a stationary bed of grinding or polishing media. Since the work pieces never touch each other during the process, they cannot scratch or nick each other.

to overview